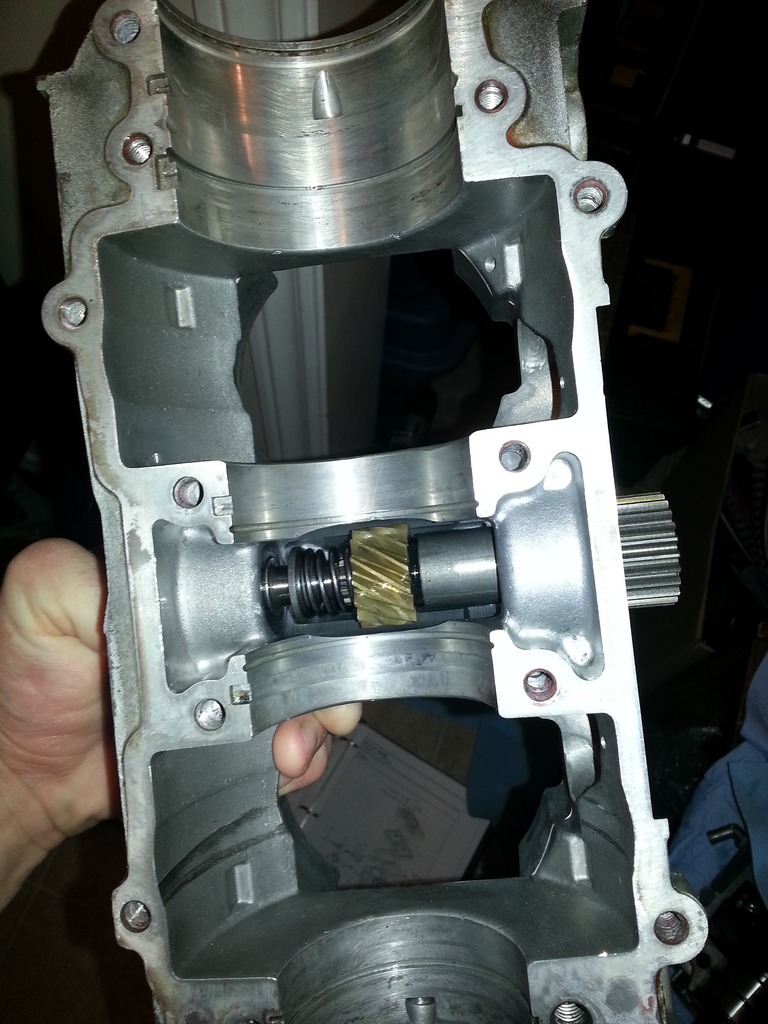

Just assembling my top case half and I've noticed a bit of a problem

1. the old bearing didn't have a seal on the back side of the inner bearing of the rotary shaft. You know, the one that stay's in the case.

Also there was some fluid back there that was a different color than what was in the rotary bath. ( looked like synthetic xps)

2. The new bearing I have is sealed on both sides.

Should I remove the outer seal and fill the cavity with some sort of oil ? 30w ?

or should I just asemble it the way it is with both seals in tact and leave the cavity empty ?

It is a sealed cavity...

Thanks

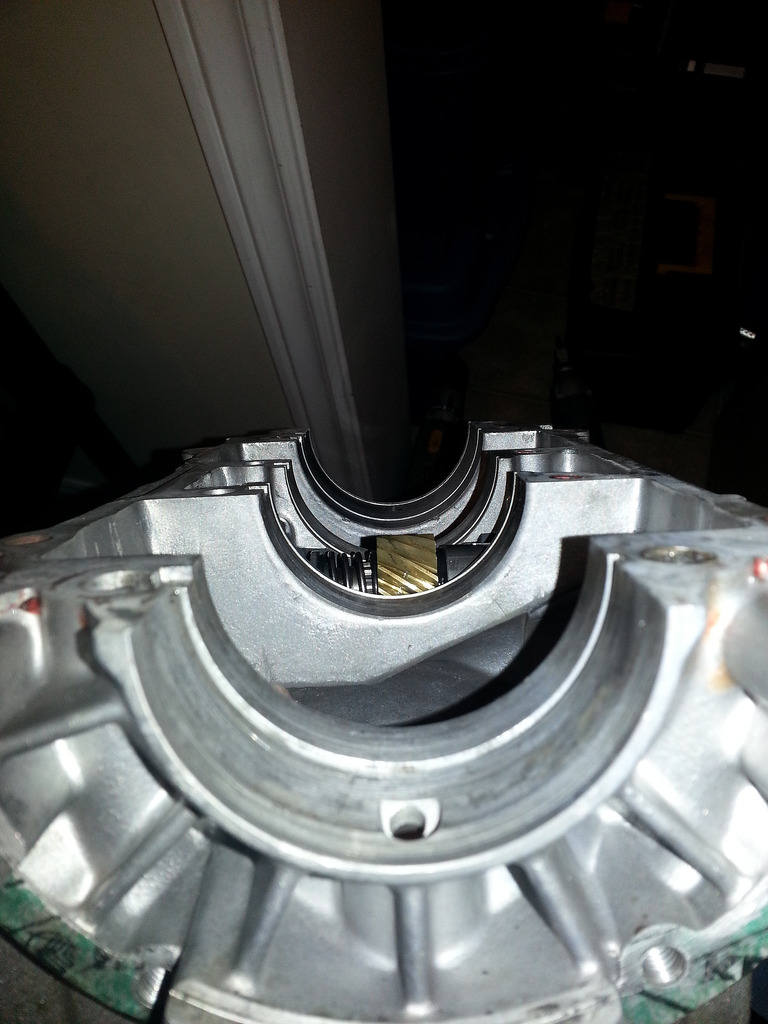

1. the old bearing didn't have a seal on the back side of the inner bearing of the rotary shaft. You know, the one that stay's in the case.

Also there was some fluid back there that was a different color than what was in the rotary bath. ( looked like synthetic xps)

2. The new bearing I have is sealed on both sides.

Should I remove the outer seal and fill the cavity with some sort of oil ? 30w ?

or should I just asemble it the way it is with both seals in tact and leave the cavity empty ?

It is a sealed cavity...

Thanks

Last edited by a moderator: