seadooaddiction

Active Member

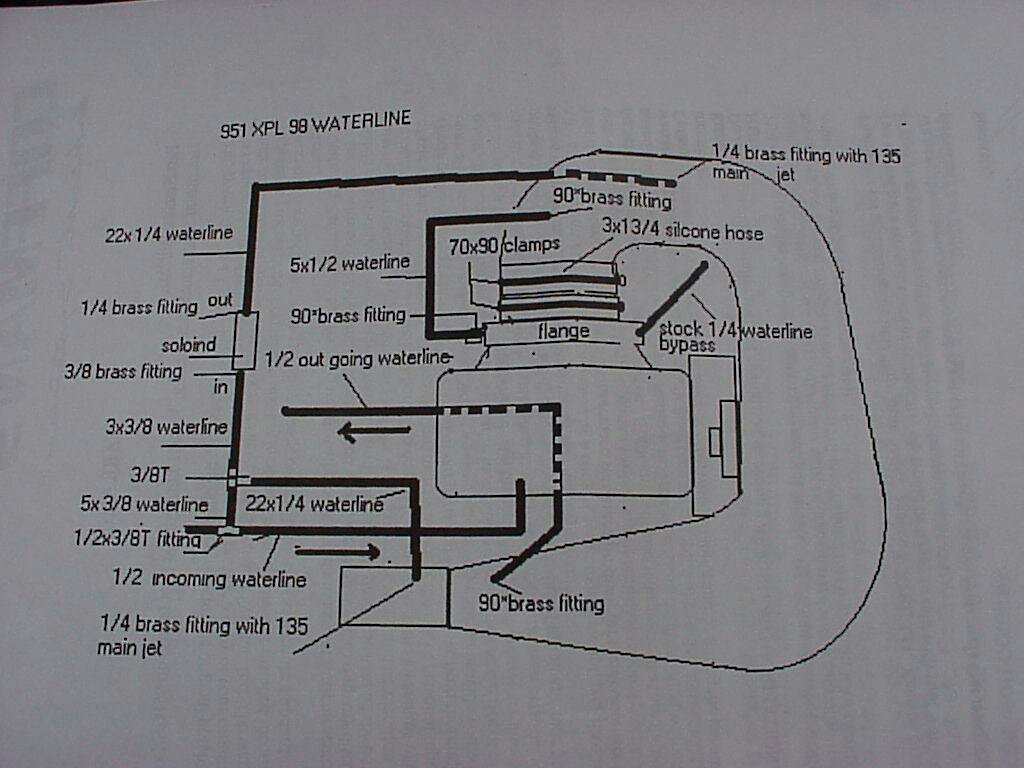

So I added a dual cooling setup to my XPL Coffman build since I didn't like how hot the pipe was running. After I installed the dual cooling the machine just feels much lazier and is no where near as responsive. The ski lost 100 revs on top and seems to have developed a miss when I hold WOT and load the pump with a left hand sweeping turn.

Im thinking the coffman is designed to run hot. Its never sizzled water after a moto but will burn ya if u touch it for too long when running the standard setup spec'd by coffman.

Anyway. Why would adding more water to the water jacket effect engine performance? The same amount of water is being introduced into thr expansion chamber and jetting did not change. I did just fuel up before test with 93 octane so perhaps bad fuel?

Any thoughts appreciated. Thanks

Im thinking the coffman is designed to run hot. Its never sizzled water after a moto but will burn ya if u touch it for too long when running the standard setup spec'd by coffman.

Anyway. Why would adding more water to the water jacket effect engine performance? The same amount of water is being introduced into thr expansion chamber and jetting did not change. I did just fuel up before test with 93 octane so perhaps bad fuel?

Any thoughts appreciated. Thanks