hess996

New Member

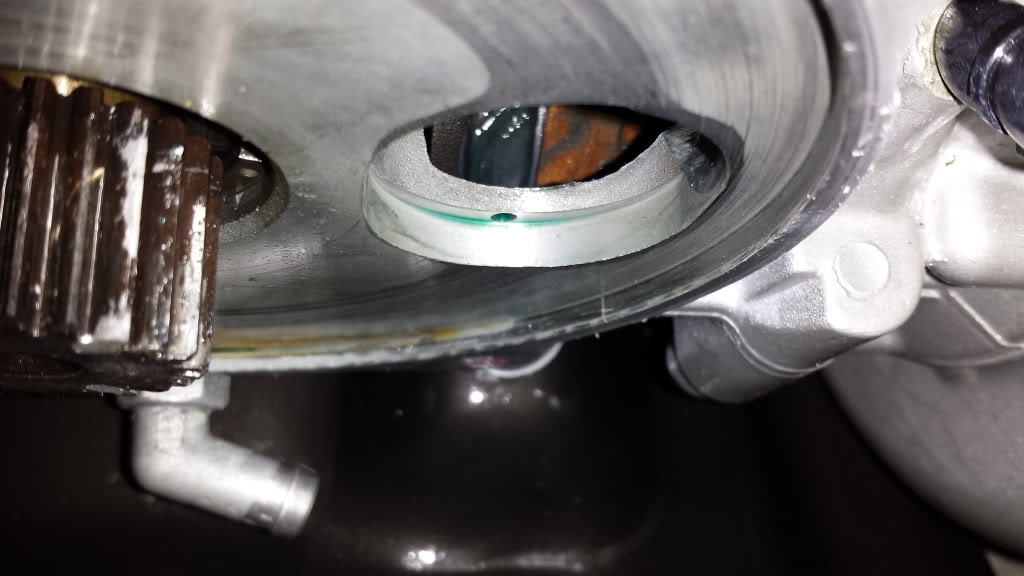

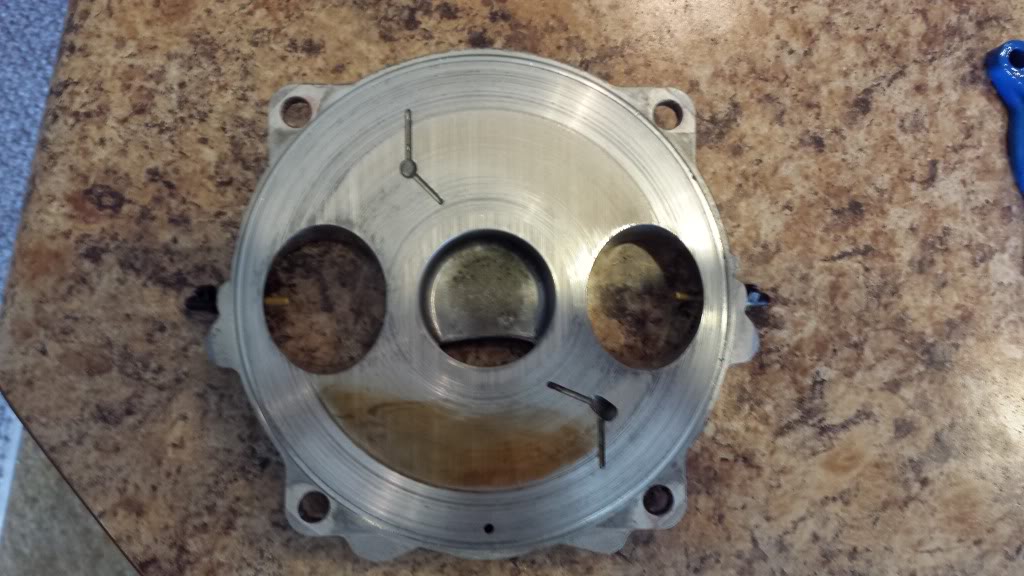

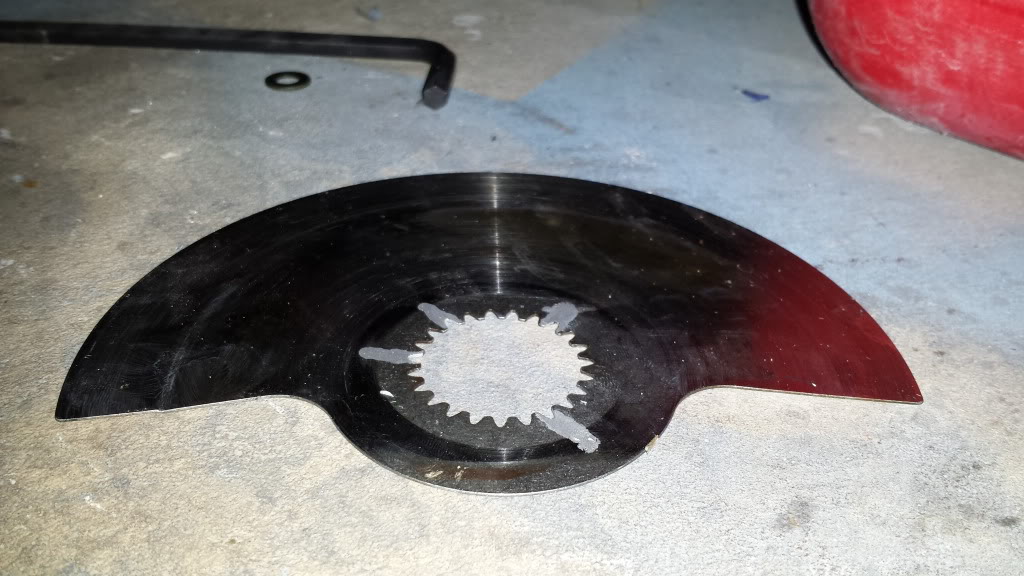

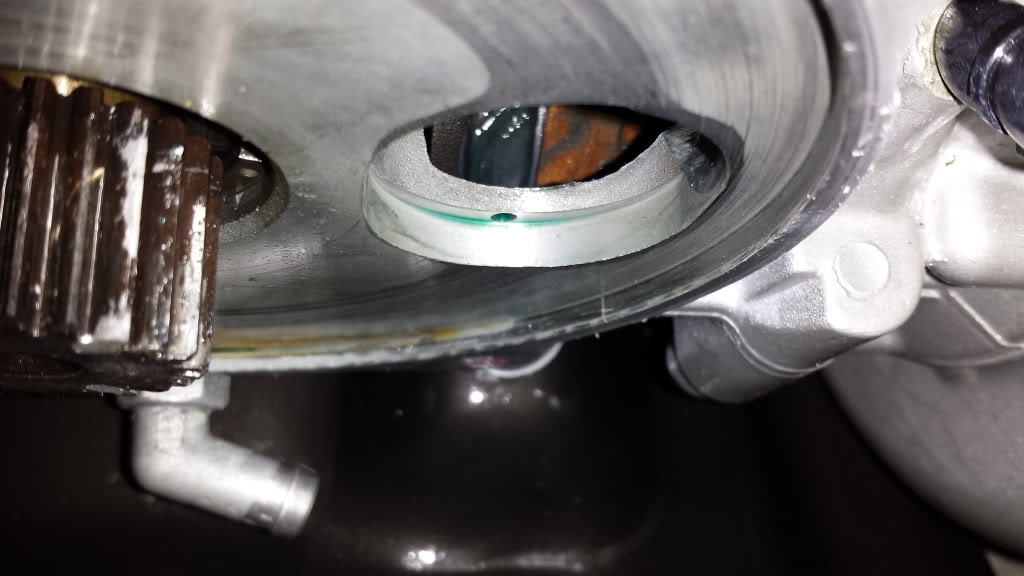

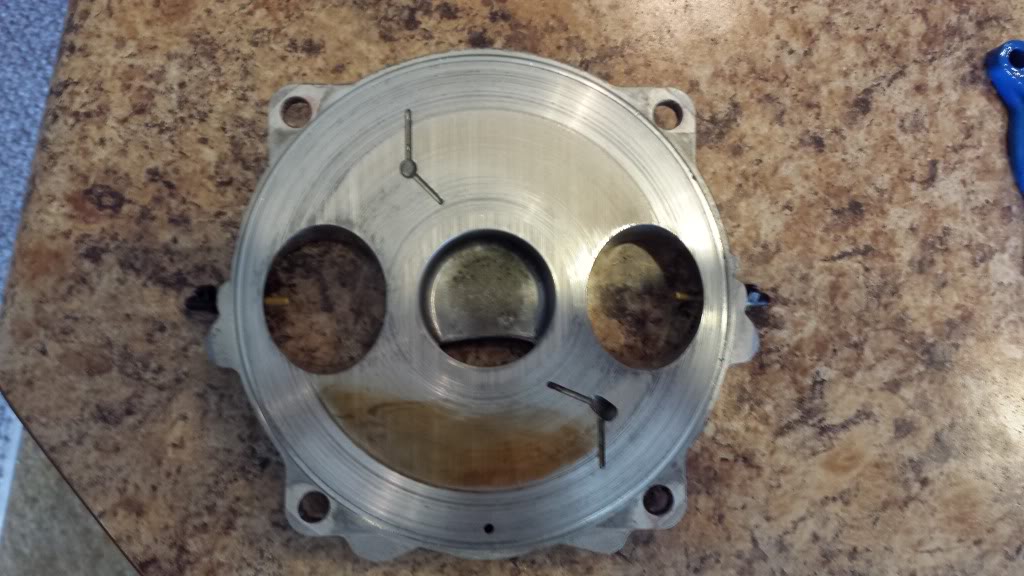

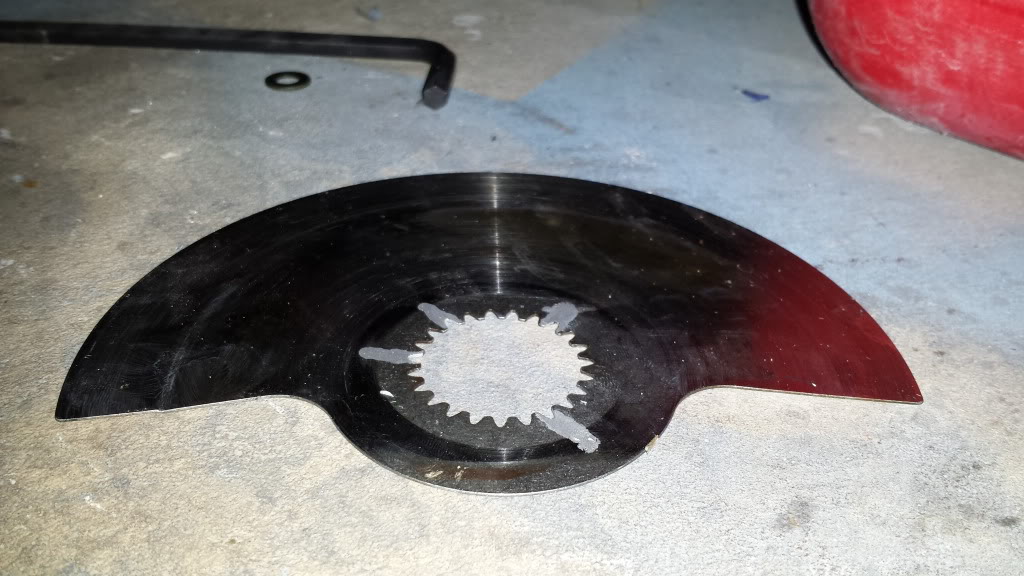

Ok long story story I have been doing a rebuild/customizing on my 1996 seadoo speedster with the twin 717. I kinda had a goal that even though I have never done anything like this before, I wanted to try doing it solo just by doing some good old fashion research. I have the full top end rebuilt and is all perfect in factory spec. The crank all looked good as far as wear and tear and factory check specs, so i left that, the rotary valve, pto and flywheel alone. I decided im going to premix. Pulled the oil tank lines etc and began to pull the oil pump out. Since I had to pull the rotary valve cover off to remove the gear on the pump i find what seems to me to be a major problem. The rotary valve cover, rotary valve and the engine block its self have major scoring. replacing the cover and valve is no problem. My question is what can I do about the damage on the block? Right on the edge of the ports has some good sized dings. Any help or direction will be very much appreciated. At this point I have around 600+ hrs in a 6 month time frame invested, so if there is anything I can do to properly fix this I will. Honestly as much as I don't want to rip the motors apart again I'm wondering where its this far if I should just go all in and get a replacement bottom end with new cases, crank, bearing, rotary valve shaft, pto and flywheel. That is if anyone makes a bottom end kit. I'm going to try to post pics to help a little more in seeing the issue. I just don't know how major or not this is. I will be doing a full post with all the info from start to finish when I get this issue fixed. Its the last thing till it all goes back in. Thanks again,

and the motors just for fun haha. Minus they dont have the blue intakes on in these pics.

Justin

and the motors just for fun haha. Minus they dont have the blue intakes on in these pics.

Justin

Last edited by a moderator: