alexd51

New Member

So i been working on my challenger 1800 and every time i fix one thing either i break or it breaks because is old. Well i cleaned the fuel tank as well as the oil tank, changed fuel filters and oil filter and also most of the oil lines . After working on this boat for almost 3 weeks i was ready to test but before i bleed the oil lines and when i got done it was too late to start the engine just because of my neighbors so i left it for the next day.

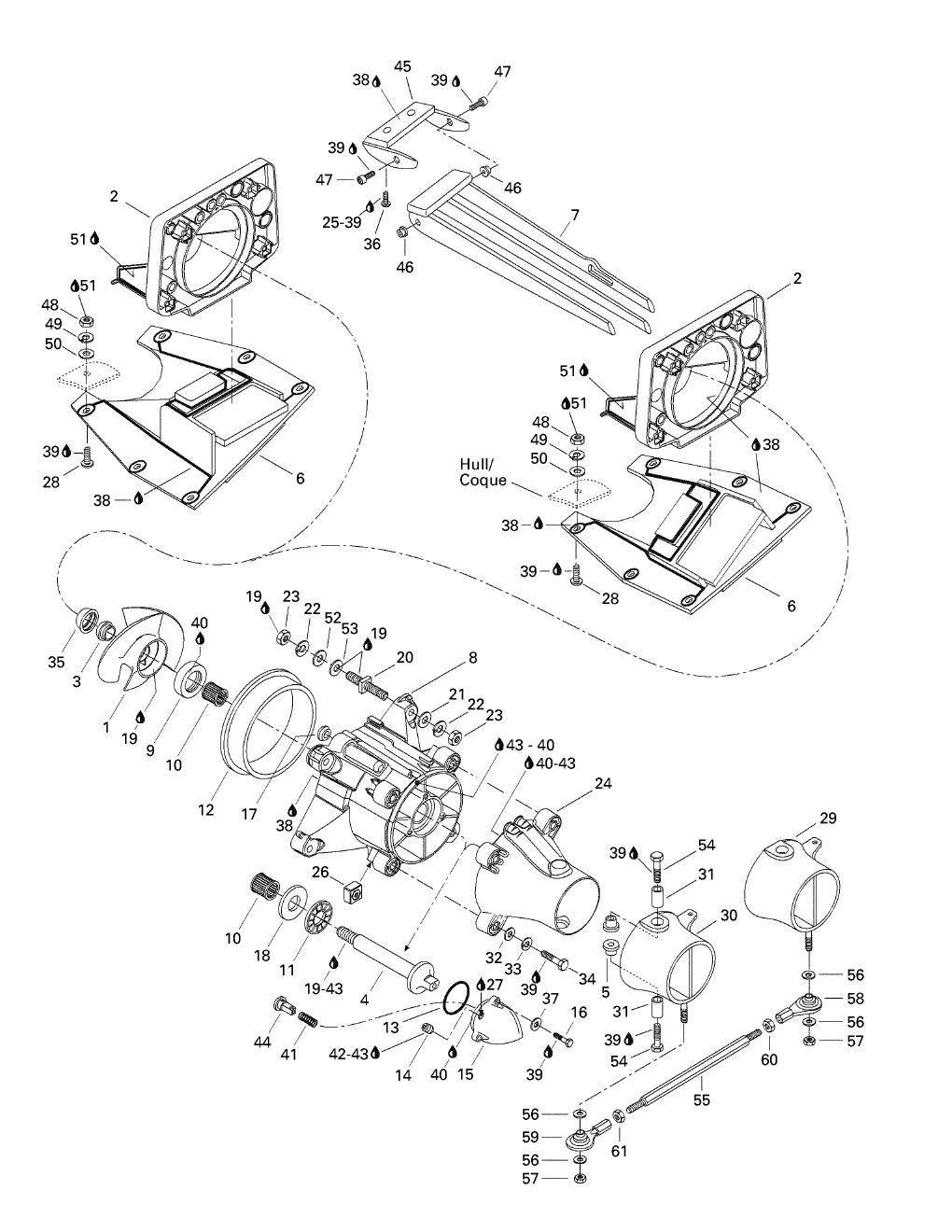

Well today is the next day, i got up early and while drinking my morning coffee i walked over to the boat and i find that all the oil i left in the tank the night before is now covering the floor of my carport. I dont get a break, well after double checking all the hoses none of them are leaking i look all over and finally find the oil is coming from under the port side motor specifically under the exhaust.

Well i think i was going to be able to take part of the exhaust out and fix the leak but after removing the 2 bolts holding the pipe i still cant get it out, well thats fine i think if i take the part that is connected to the manifold i will be able to take it all out and fix the leak or im wrong???

Now my question about the gasket is, is this a regular sort of compressed cardboard gasket or something else? only asking because i have diferent gasket making material from other projects and i rather do one that spending $13.95 for a gasket.

Well today is the next day, i got up early and while drinking my morning coffee i walked over to the boat and i find that all the oil i left in the tank the night before is now covering the floor of my carport. I dont get a break, well after double checking all the hoses none of them are leaking i look all over and finally find the oil is coming from under the port side motor specifically under the exhaust.

Well i think i was going to be able to take part of the exhaust out and fix the leak but after removing the 2 bolts holding the pipe i still cant get it out, well thats fine i think if i take the part that is connected to the manifold i will be able to take it all out and fix the leak or im wrong???

Now my question about the gasket is, is this a regular sort of compressed cardboard gasket or something else? only asking because i have diferent gasket making material from other projects and i rather do one that spending $13.95 for a gasket.