M2 Jet Drive is not a Rock Crusher :-( UPDATED WITH PICS and Measurements

Hello All,

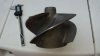

Found a very nice unmarked rock pile this weekend with my 2000 Islandia. Shut it down as soon depth finder alarmed at 4 feet, but apparently wasn't quick enough. :facepalm: "Clunk" and no start. Pulled her back to launch, spent a few hours digging out a few rocks that were wedged between the vanes of the impeller, and between the impeller and stator. Got it all cleaned out and rinsed out, went out for a shakedown cruise. all seemed well :thumbsup:, until we put the tube on and tried to drag the kids around.

Lot's of what I am assuming is cavitation, and a knocking sound from the back of boat with synchronized vibration at the shift lever. At least the shift lever can keep a beat.. about 1 thunk per second.

Idled back to shore quietly and called it a weekend. I am assuming that the impeller and stator are now due for a rebuild, but want to see if there is anything else to check while I have her apart.. Thanks for any information, I will attach a few pics of the areas I am concerned with.

Joel

![20150731_201920[1].jpg 20150731_201920[1].jpg](https://www.seadooforum.com/data/attachments/24/24913-e1441ccb32f9ac40305a75cf620d9862.jpg?hash=4UQcyzL5rE)

![20150802_135453[1].jpg 20150802_135453[1].jpg](https://www.seadooforum.com/data/attachments/24/24912-890e59655316e4029511a3460188dfa9.jpg?hash=iQ5ZZVMW5A)

![20150802_135453[1].jpg 20150802_135453[1].jpg](https://www.seadooforum.com/data/attachments/24/24912-890e59655316e4029511a3460188dfa9.jpg?hash=iQ5ZZVMW5A)

Hello All,

Found a very nice unmarked rock pile this weekend with my 2000 Islandia. Shut it down as soon depth finder alarmed at 4 feet, but apparently wasn't quick enough. :facepalm: "Clunk" and no start. Pulled her back to launch, spent a few hours digging out a few rocks that were wedged between the vanes of the impeller, and between the impeller and stator. Got it all cleaned out and rinsed out, went out for a shakedown cruise. all seemed well :thumbsup:, until we put the tube on and tried to drag the kids around.

Lot's of what I am assuming is cavitation, and a knocking sound from the back of boat with synchronized vibration at the shift lever. At least the shift lever can keep a beat.. about 1 thunk per second.

Idled back to shore quietly and called it a weekend. I am assuming that the impeller and stator are now due for a rebuild, but want to see if there is anything else to check while I have her apart.. Thanks for any information, I will attach a few pics of the areas I am concerned with.

Joel

![20150731_201920[1].jpg 20150731_201920[1].jpg](https://www.seadooforum.com/data/attachments/24/24913-e1441ccb32f9ac40305a75cf620d9862.jpg?hash=4UQcyzL5rE)

![20150802_135453[1].jpg 20150802_135453[1].jpg](https://www.seadooforum.com/data/attachments/24/24912-890e59655316e4029511a3460188dfa9.jpg?hash=iQ5ZZVMW5A)

![20150802_135453[1].jpg 20150802_135453[1].jpg](https://www.seadooforum.com/data/attachments/24/24912-890e59655316e4029511a3460188dfa9.jpg?hash=iQ5ZZVMW5A)

Last edited by a moderator: