Danosll

Active Member

First thanks to everybody on this forum .both to people who replied to my questions and posters who threads I have read. It's what has pointed me in the right direction to get this boat running so well.

787 challenger single.

After I installed new impeller motor would only rev to 5500rpm. Now after going through carbs ,raves, and water regulator on exhaust . Will turn 6800 rpm .

Idles great But still has bad miss at 1/4 throttle, and after extended idling through no wake zone will only rev to 5500 rpm.after a couple minutes with finally start to pull strong up to 6800rpm. So my issue is basically mid range.

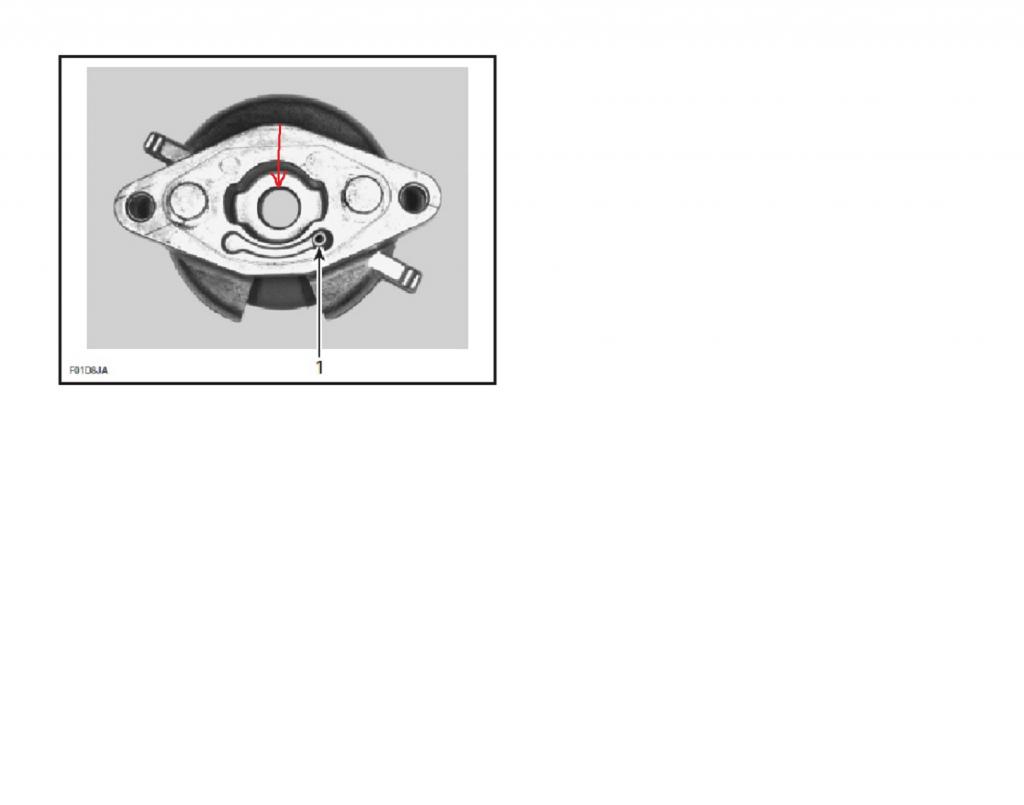

150+ compression. rebuilt carbs pop off equal and within specs . Low speed adjuste 1 1/4 high speed turned in fully clockwise (with cap on right?) I didn't record low and Hs jet sizes.but I rember pop off spring silver and 1.5 seat. Fuel pump tested good according to manual.Ran fuel line directly to pick up baffle by passed selector valve. Cleaned rave valve,replaced 1valve and piston,bellows.adjusters turned in all the way. Check water regulator valve and adjuster flush. Plugs are always a good colour. But I never checked colour after pinned at 5500 rpm but I assume it is rich.

Running injector with semi synthetic low ash non tw3. Was running full synthetic but had to change . Seemed to run better with full synthetic . So I will change back when low.

What do you think? And thanks

787 challenger single.

After I installed new impeller motor would only rev to 5500rpm. Now after going through carbs ,raves, and water regulator on exhaust . Will turn 6800 rpm .

Idles great But still has bad miss at 1/4 throttle, and after extended idling through no wake zone will only rev to 5500 rpm.after a couple minutes with finally start to pull strong up to 6800rpm. So my issue is basically mid range.

150+ compression. rebuilt carbs pop off equal and within specs . Low speed adjuste 1 1/4 high speed turned in fully clockwise (with cap on right?) I didn't record low and Hs jet sizes.but I rember pop off spring silver and 1.5 seat. Fuel pump tested good according to manual.Ran fuel line directly to pick up baffle by passed selector valve. Cleaned rave valve,replaced 1valve and piston,bellows.adjusters turned in all the way. Check water regulator valve and adjuster flush. Plugs are always a good colour. But I never checked colour after pinned at 5500 rpm but I assume it is rich.

Running injector with semi synthetic low ash non tw3. Was running full synthetic but had to change . Seemed to run better with full synthetic . So I will change back when low.

What do you think? And thanks