1983

Well-Known Member

What's up guys?

Question for you all on my 96' XP. Its been running great, pulled 6900 RPMS on the last ride, no issues with how it runs, just cavitating out of the hole due to wear ring completely shot.

So only thing that has changed was what I did saturday:

I replaced wear ring, jet drive oil, and neoprene hull to pump seal. Sealed everything up correctly with RTV to hull around bailer and pump tubes, made sure pump shaft bearing and washer went back to correct placement and everything spins freely. Everything installed to a T. Went to ride it yesterday and it accelerates so much better, pulls better through mid range, and even feels faster on top end. But im only pulling at most 6450 rpms now

Also I installed R+D nozzles setup I had laying around. Could that be restricting RPMs or something? Also, water wasn't like glass out there, but was decent enough to where I should be able to get RPMs like I used to in the higher 6k range.. where did my RPMs go?

Break in period for new wear ring or something?

Rob

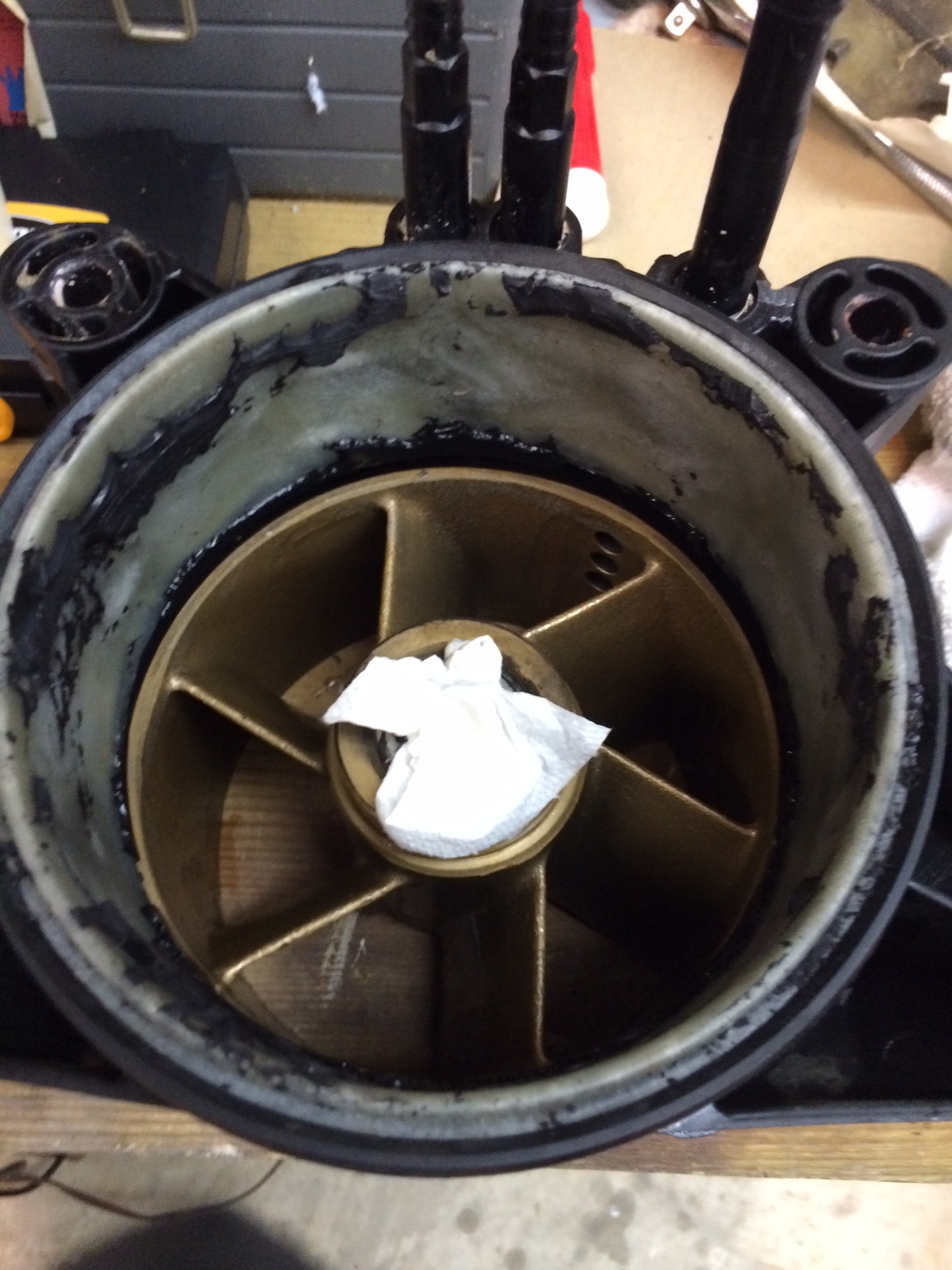

Before:

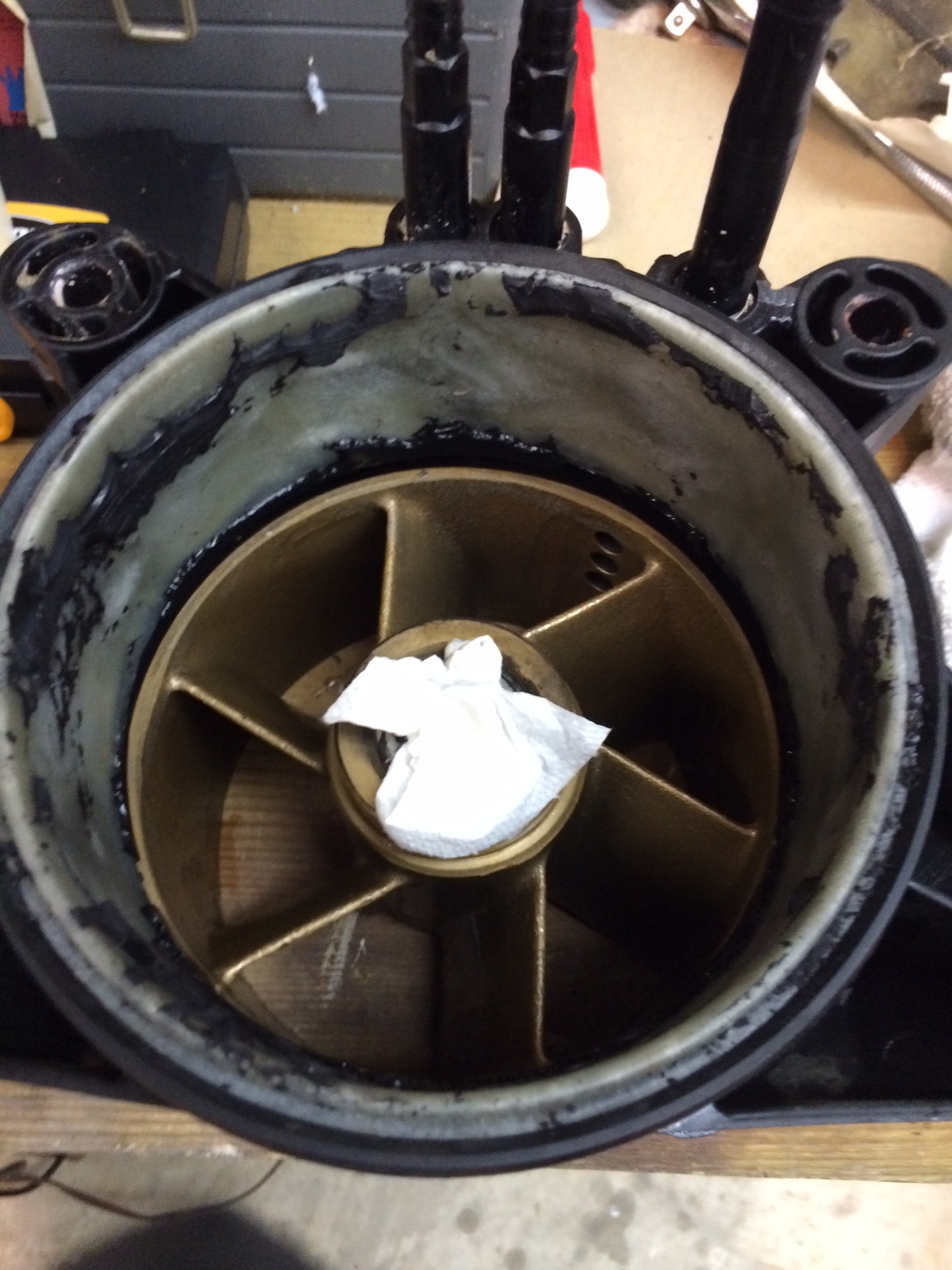

After:

Question for you all on my 96' XP. Its been running great, pulled 6900 RPMS on the last ride, no issues with how it runs, just cavitating out of the hole due to wear ring completely shot.

So only thing that has changed was what I did saturday:

I replaced wear ring, jet drive oil, and neoprene hull to pump seal. Sealed everything up correctly with RTV to hull around bailer and pump tubes, made sure pump shaft bearing and washer went back to correct placement and everything spins freely. Everything installed to a T. Went to ride it yesterday and it accelerates so much better, pulls better through mid range, and even feels faster on top end. But im only pulling at most 6450 rpms now

Also I installed R+D nozzles setup I had laying around. Could that be restricting RPMs or something? Also, water wasn't like glass out there, but was decent enough to where I should be able to get RPMs like I used to in the higher 6k range.. where did my RPMs go?

Break in period for new wear ring or something?

Rob

Before:

After:

Last edited by a moderator: