-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is this little fitting necessary?

- Thread starter ricardo1

- Start date

- Status

- Not open for further replies.

Sportster-2001-951C-Stock

Well-Known Member

You gonna stick a cork in the hole there?

ricardo1

Active Member

I don't want to buy a set of cases, new gaskets and put the engine back together after just getting a full rebuild just for that little nipple that might not be a must, you feel me? I wouldn't mind buying the fitting if they had it but they don't and the size is not in home depot, lowes, napa, advance, auto zone etc.

Sportster-2001-951C-Stock

Well-Known Member

I don't want to buy a set of cases, new gaskets and put the engine back together after just getting a full rebuild just for that little nipple that might not be a must, you feel me? I wouldn't mind buying the fitting if they had it but they don't and the size is not in home depot, lowes, napa, advance, auto zone etc.

Okay, doesn't look so hard to me though, I must be stupid or something.

ricardo1

Active Member

It goes on the bottom of the engine and it looks like an oil return or maybe a vent , little black hose that mets with a T and other 2 lines infront of the ski and have a little green square box.

There is no way to get that fitting unless you buy another set of cases.

Sent from my Samsung GALAXY S4 using Tapatalk 2

There is no way to get that fitting unless you buy another set of cases.

Sent from my Samsung GALAXY S4 using Tapatalk 2

Strizzo

Well-Known Member

to me, it looks like someone replaced the pipe plug drain plug in the counterbalance cavity and replaced it with a hose fitting for easy drain and refill. are you sure this is indeed a factory part, or that you can't just replace it with another pipe plug barbed fitting?

By looking as some cases........ Correct me if I'm wrong but is that where the pump is for the DI? On the top half of the case you have a "squirter" that will introduce oil into that area to keep the piston and rod lubed. So, that is your oil drain, the oil has to go some where. I'll assume that you broke it? Time to split the cases and pull the broken one, tap the hole and get a fitting that threads in. It's probably a specific size so the oil doesn't drain out too fast.

So yeah, it's important

So yeah, it's important

ricardo1

Active Member

SES called me to tell me it was missing from day one before he got to work on it, so is not broken and its inside the cases because he just rebuield the entire engine, maybe it came off on shipping or something not sure. He did mention its the drain/ return for the oil and the compressor.

Sportster-2001-951C-Stock

Well-Known Member

The machine shop is supposed to clean and chase all threads, remove any broken parts, stuff like that, there is a huge difference between a remanufactured and a rebuilt motor, the latter is often accomplished using only a spray can and the former is actually machined, precision measured and castings cleaned and professionally, repaired as necessary.

So, the hole in your block should be prepped and ready for a proper fitting, yet still we don't have the benefit of a photo so we still don't know what you're looking at, for some reason. Never mind that I'm surprised SES didn't just install one, I feel like they should've done that but it's not a show stopper, at least I don't see why it would be.

So, the hole in your block should be prepped and ready for a proper fitting, yet still we don't have the benefit of a photo so we still don't know what you're looking at, for some reason. Never mind that I'm surprised SES didn't just install one, I feel like they should've done that but it's not a show stopper, at least I don't see why it would be.

Sportster-2001-951C-Stock

Well-Known Member

How about something like this fitting?

http://www.ebay.com/itm/Pro-Series-...Parts_Accessories&hash=item485acd5efe&vxp=mtr

Or maybe if there are no threads, you need a press in fitting. In that case a matching piece of non-threaded tubing, perhaps 1/4"od or whatever the hole size you measure might work depending on the size of the hole, a fitting that swages into the hole by driving it in tight with a small hammer. Don't drive it in too deep, to hit the rotating parts, measure the depth of the hole and mark the fitting.

http://www.proflange.com/products.php?content=nipples

But, the machine shop should have driven out or removed any broken pieces from the inside(regardless if it's a threaded or press-in fitting). Call and tell them this first, if you have to remove the case bottom, they should've at least cleaned up and prepared the hole even if they didn't intend on providing a proper fitting.

http://www.ebay.com/itm/Pro-Series-...Parts_Accessories&hash=item485acd5efe&vxp=mtr

Or maybe if there are no threads, you need a press in fitting. In that case a matching piece of non-threaded tubing, perhaps 1/4"od or whatever the hole size you measure might work depending on the size of the hole, a fitting that swages into the hole by driving it in tight with a small hammer. Don't drive it in too deep, to hit the rotating parts, measure the depth of the hole and mark the fitting.

http://www.proflange.com/products.php?content=nipples

But, the machine shop should have driven out or removed any broken pieces from the inside(regardless if it's a threaded or press-in fitting). Call and tell them this first, if you have to remove the case bottom, they should've at least cleaned up and prepared the hole even if they didn't intend on providing a proper fitting.

After a little leg work, I think that fitting supplies the air pressure to your RAVE valves, I assume it goes to the solenoid that activates your RAVES? So, without it your RAVEs are not gonna work.

Does it got to this

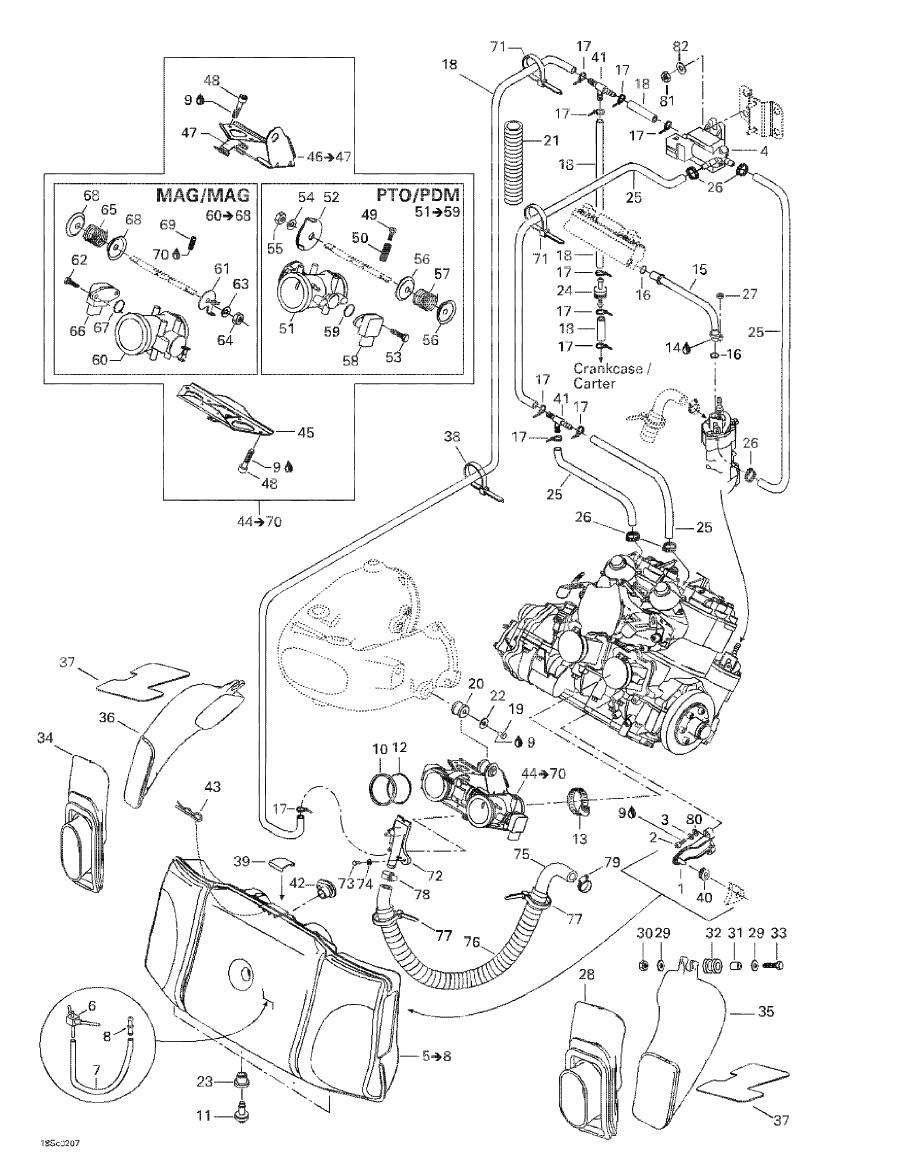

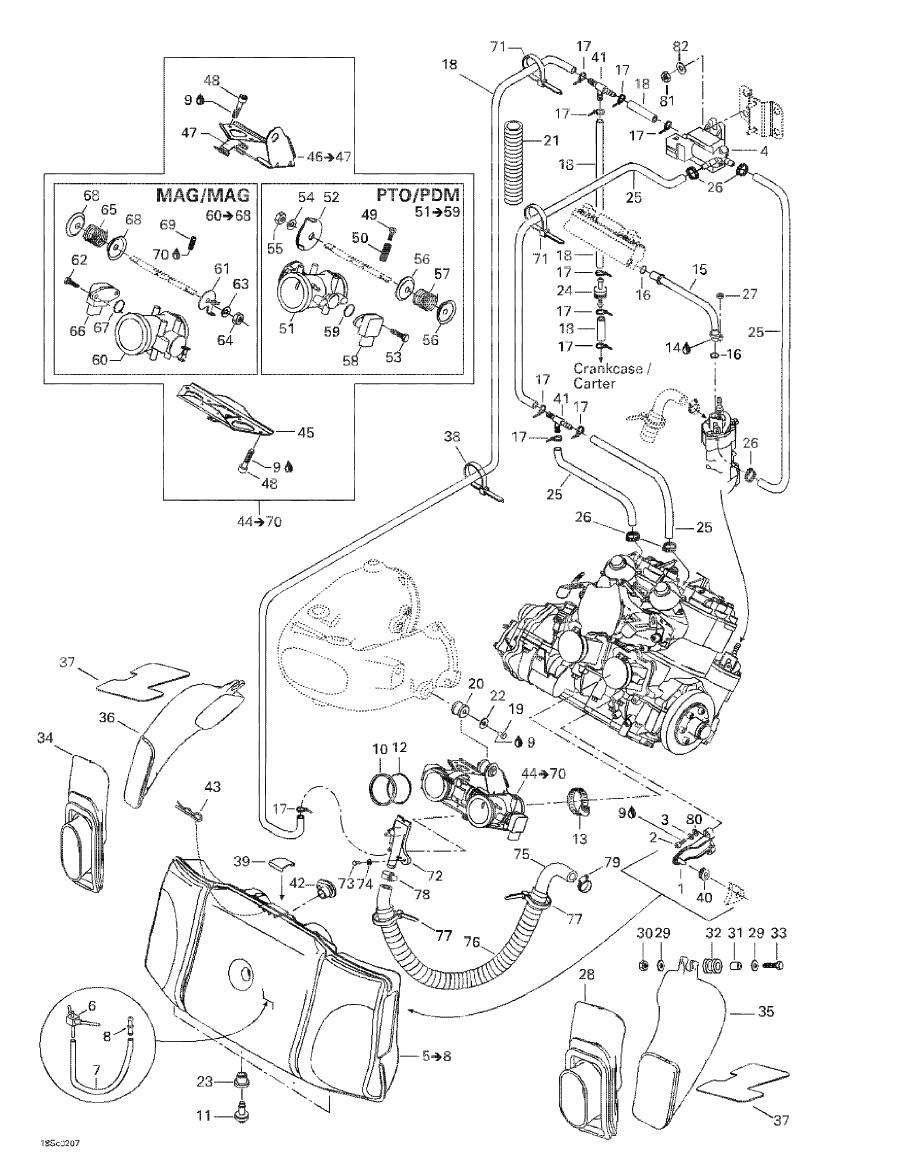

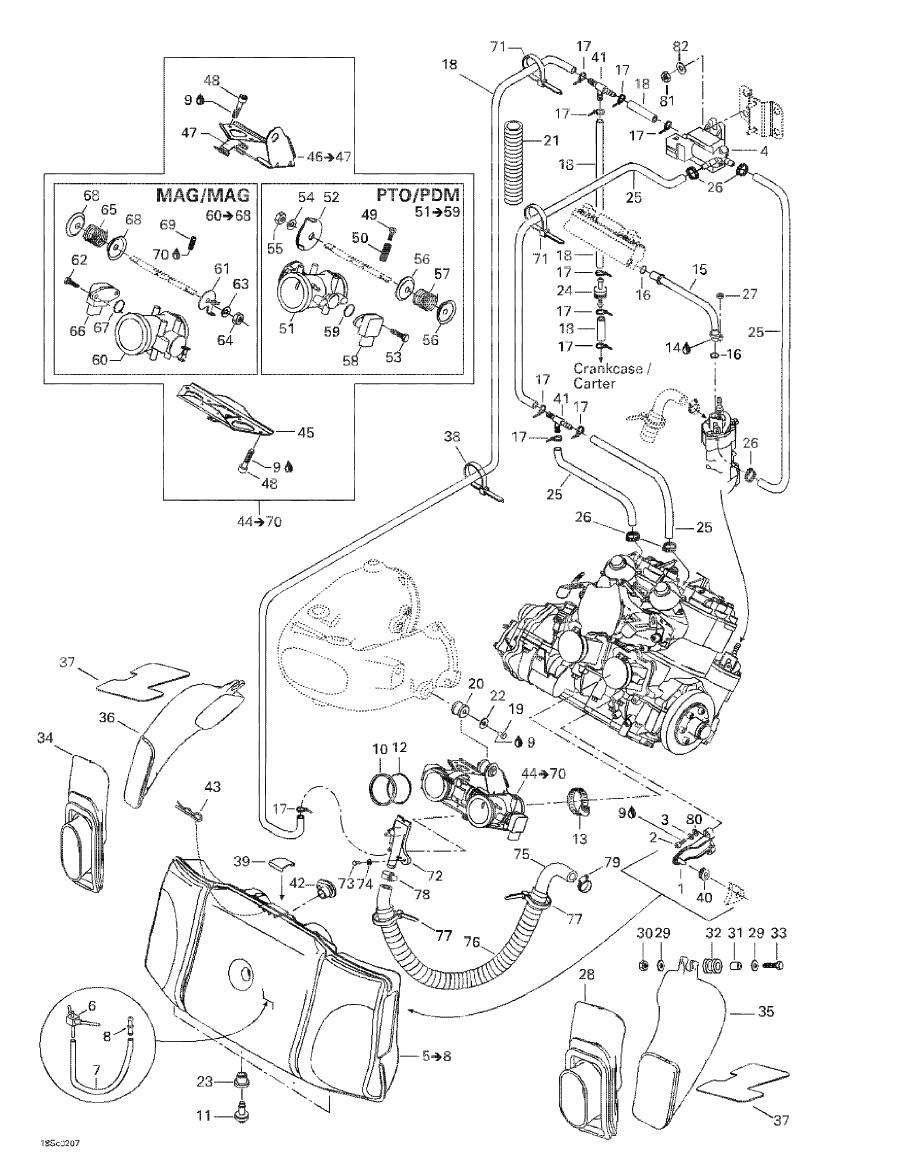

Here is the fiche where you can seed the hose that says CRANKCASE

Does it got to this

Here is the fiche where you can seed the hose that says CRANKCASE

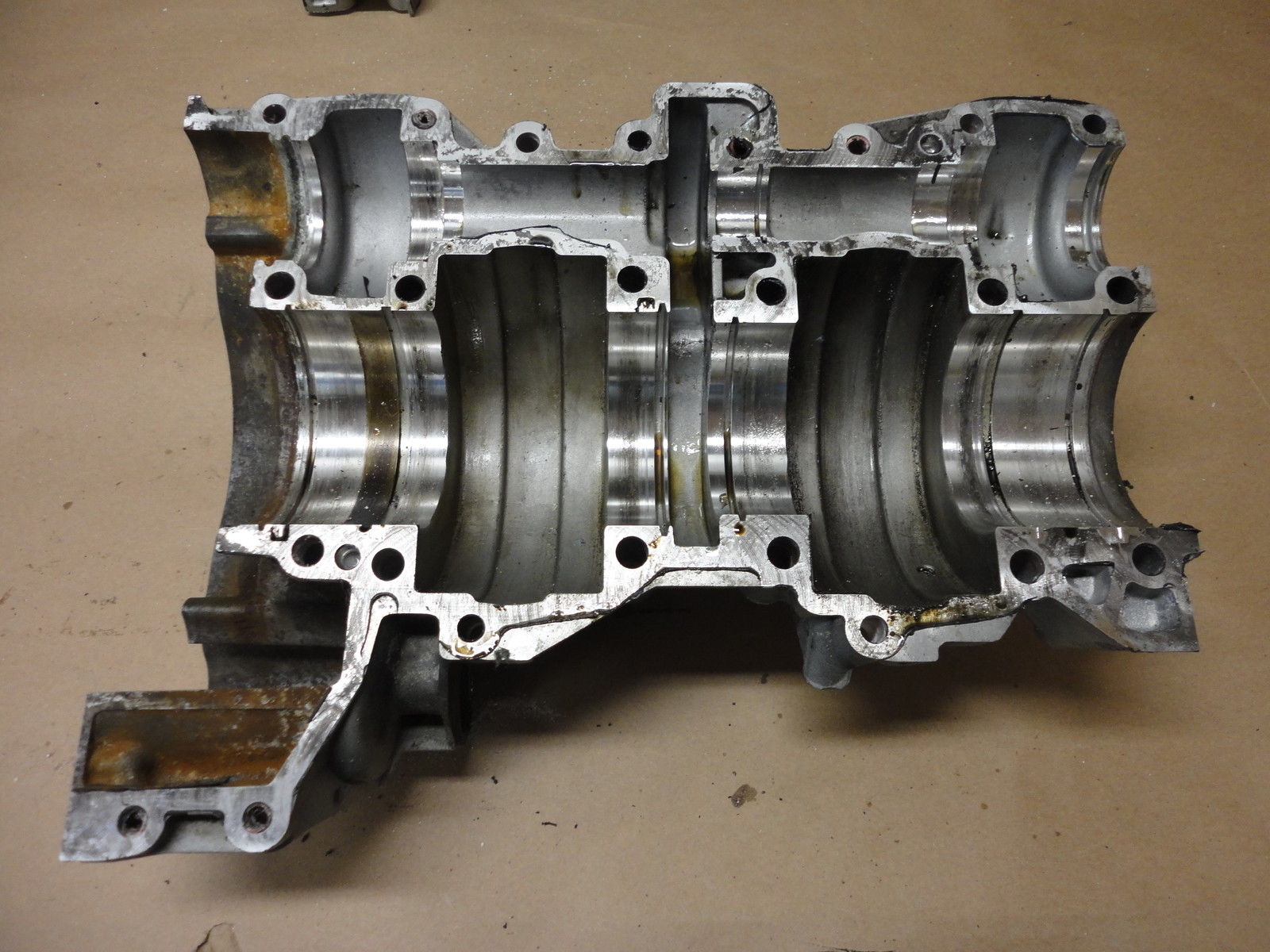

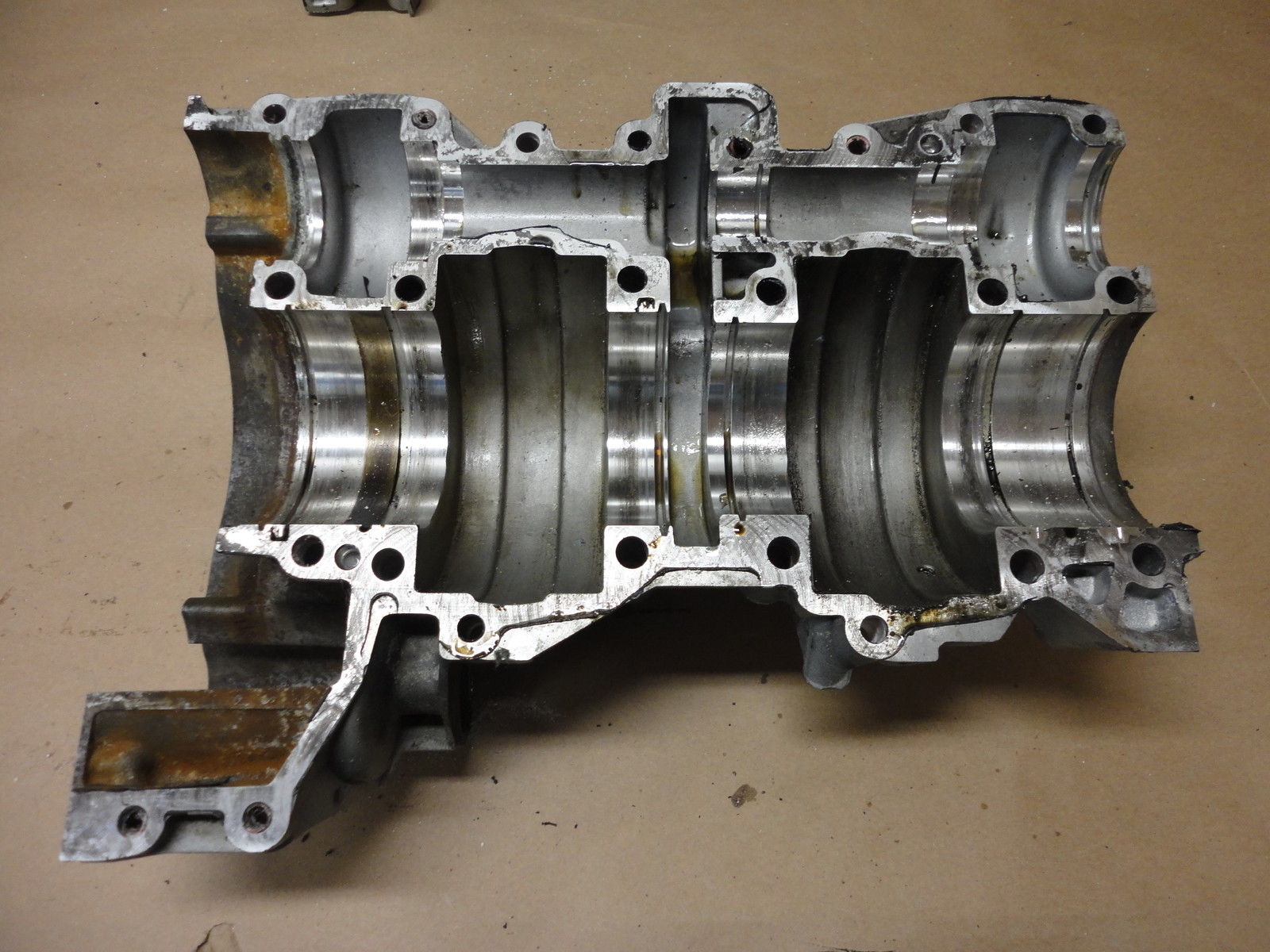

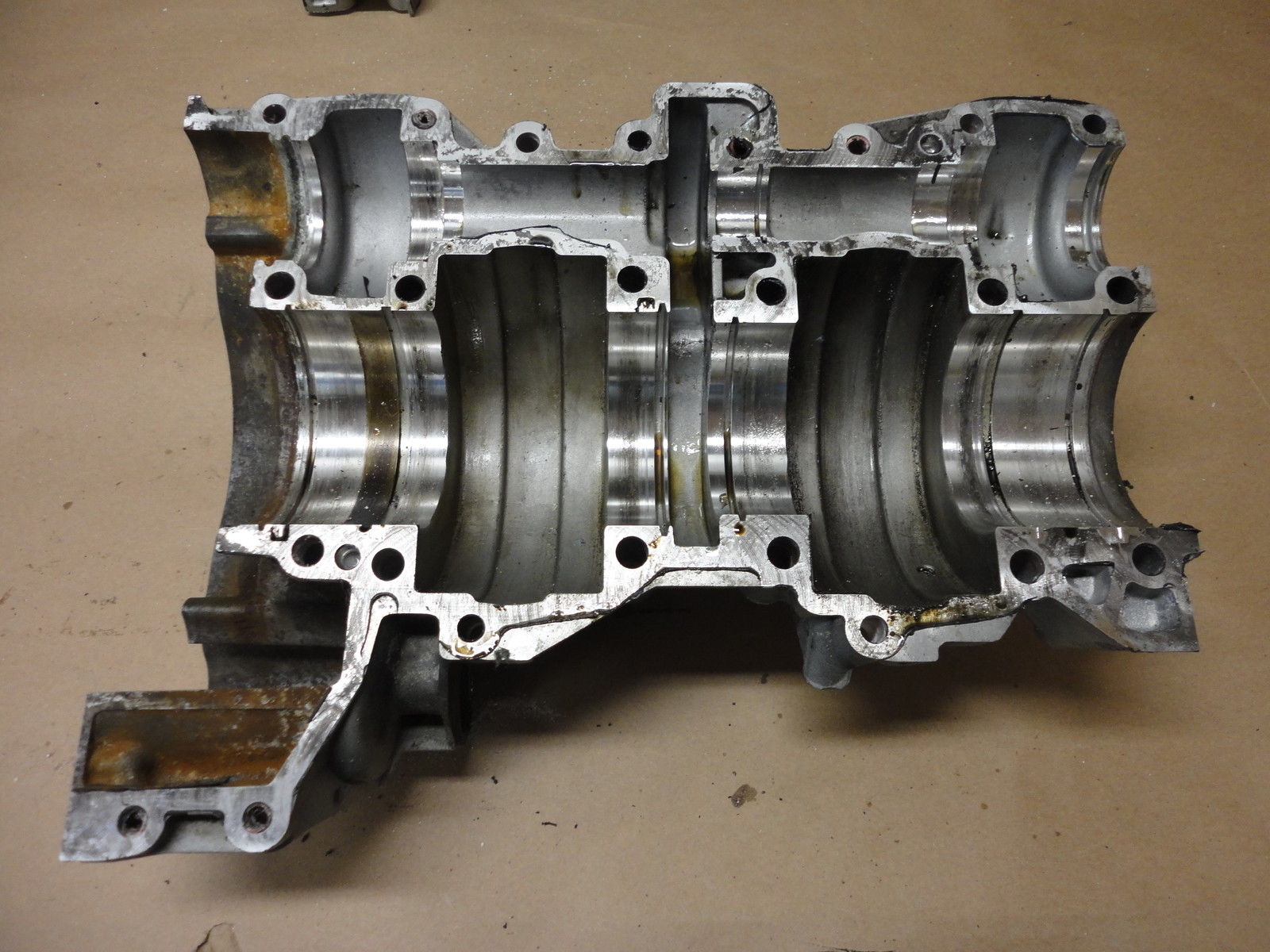

Like I said before, I think it's gonna have to come apart, if you want to do it the right way. If you look in this pic in the top right you will see where the port it, that is not tapped or else you would see thread on that fitting. It's just like the injection nipples--pressed in so they can clock them exactly how they want it. It might not be what's supplying the pressure I think but perhaps providing the "pulse" for it to function? Regardless of it's function, it's gotta be fixed.

The problem you're going to face is this. It's virtually impossible to get an 1/8 NPT to a hose barbed fitting in 90 degrees, to a 3/16 hose barb, so you're going to have to get creative and use 2 pieces.

This would be ideal but it's 1/4NPT to 1/4" tube, can't get it in 3/16 barb.

So you'll have to make it 2 pieces

First piece 1/8 NPT 90 deg fitting

http://www.mcmaster.com/#50785k41/=oskuxc

Second piece 1/8 NPT to 3/16" hose barb (I think the tube is 4.3mm or .169"--3/16 is .187")

http://www.mcmaster.com/#5346k11/=osktyi

To This

There you go it's all fixed, now you just need to do the labor.

This would be ideal but it's 1/4NPT to 1/4" tube, can't get it in 3/16 barb.

So you'll have to make it 2 pieces

First piece 1/8 NPT 90 deg fitting

http://www.mcmaster.com/#50785k41/=oskuxc

Second piece 1/8 NPT to 3/16" hose barb (I think the tube is 4.3mm or .169"--3/16 is .187")

http://www.mcmaster.com/#5346k11/=osktyi

To This

There you go it's all fixed, now you just need to do the labor.

Sportster-2001-951C-Stock

Well-Known Member

Yeah, the pressure for operating the raves actually comes from the compressor head, I think? This missing fitting is the oil drain off the bottom of the compressor crankcase, I think? There's an oil supply line that comes in on the side of the compressor to lube the compressor and the idea is this oil would fill the compressor crankcase and hydrolock it if there was no oil return drain at the bottom?

Then this oil collected gets blown back to the oil tank when the rave solenoid cycles, pressure off the rave solenoid exhaust, it blows the collected oil back toward and into the oil tank.

Or, that what it looks like to me, from looking over the various plumbing diagrams.

There are parts of this that aren't clear to me though, such as if the fitting is pressed in or threaded in. I don't hink is has to be 90*, but there may not be much clearance between there and the hull.

Say for instance a piece of 1/4od copper tubing would drive into the hole, then an elbow could be sweated onto that. Or, someone may have an old broken casting lying around (what are the chances that SES might've had one lying around, eh?) and can just rob the fitting off of that?

Then this oil collected gets blown back to the oil tank when the rave solenoid cycles, pressure off the rave solenoid exhaust, it blows the collected oil back toward and into the oil tank.

Or, that what it looks like to me, from looking over the various plumbing diagrams.

There are parts of this that aren't clear to me though, such as if the fitting is pressed in or threaded in. I don't hink is has to be 90*, but there may not be much clearance between there and the hull.

Say for instance a piece of 1/4od copper tubing would drive into the hole, then an elbow could be sweated onto that. Or, someone may have an old broken casting lying around (what are the chances that SES might've had one lying around, eh?) and can just rob the fitting off of that?

ricardo1

Active Member

He did, I tought I had the fitting so I told him not to worry about since that was the only thing missing.The machine shop is supposed to clean and chase all threads, remove any broken parts, stuff like that, there is a huge difference between a remanufactured and a rebuilt motor, the latter is often accomplished using only a spray can and the former is actually machined, precision measured and castings cleaned and professionally, repaired as necessary.

So, the hole in your block should be prepped and ready for a proper fitting, yet still we don't have the benefit of a photo so we still don't know what you're looking at, for some reason. Never mind that I'm surprised SES didn't just install one, I feel like they should've done that but it's not a show stopper, at least I don't see why it would be.

After a little leg work, I think that fitting supplies the air pressure to your RAVE valves, I assume it goes to the solenoid that activates your RAVES? So, without it your RAVEs are not gonna work.

Does it got to this

it hocks to the bottom on the cases not the raves, it comes from that same little box with 3 nipples, but it hocks on the bottom

Here is the fiche where you can seed the hose that says CRANKCASE

Like I said before, I think it's gonna have to come apart, if you want to do it the right way. If you look in this pic in the top right you will see where the port it, that is not tapped or else you would see thread on that fitting. It's just like the injection nipples--pressed in so they can clock them exactly how they want it. It might not be what's supplying the pressure I think but perhaps providing the "pulse" for it to function? Regardless of it's function, it's gotta be fixed.

no tap just goes in.

Yeah, the pressure for operating the raves actually comes from the compressor head, I think? This missing fitting is the oil drain off the bottom of the compressor crankcase, I think? There's an oil supply line that comes in on the side of the compressor to lube the compressor and the idea is this oil would fill the compressor crankcase and hydrolock it if there was no oil return drain at the bottom?

Then this oil collected gets blown back to the oil tank when the rave solenoid cycles, pressure off the rave solenoid exhaust, it blows the collected oil back toward and into the oil tank.

Or, that what it looks like to me, from looking over the various plumbing diagrams.

There are parts of this that aren't clear to me though, such as if the fitting is pressed in or threaded in. I don't hink is has to be 90*, but there may not be much clearance between there and the hull.

Say for instance a piece of 1/4od copper tubing would drive into the hole, then an elbow could be sweated onto that. Or, someone may have an old broken casting lying around (what are the chances that SES might've had one lying around, eh?) and can just rob the fitting off of that?

Sportster-2001-951C-Stock

Well-Known Member

Right, brass, copper and steel tubing are available in many different sizes, I make fittings like these quite often for old motors. I use copper tubing from the hardware store, steel brake line tubing from the autoparts store, and various tubing from lengths I've collected over the years.

Here are some that I salvaged from an old manifold or something and just found lying in my toolbox:

Here are some that I salvaged from an old manifold or something and just found lying in my toolbox:

Attachments

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 413

- Replies

- 1

- Views

- 424

- Replies

- 2

- Views

- 547

- Replies

- 7

- Views

- 399