BIGTEX2010

New Member

I apologize in advance if this is in the wrong spot, if it is, then please have an admin move it accordingly.

When I was rebuilding a 1994 SPI for my girlfriend I needed to recover the seat, well in my search to find a “How To” on the subject, I came up empty. So I figured I would write my own when it came time to recover my SPX seat.

DISCLAIMER: THIS IS THE WAY THAT I FOUND WORKED BEST FOR ME, THERE IS VIRTUALLY 100 PLUS WAYS TO DO THIS, SO WHAT EVER WAY YOU FIND WORKS BEST FOR YOU IS THE WAY THAT YOU WILL WANT TO DO THIS. REMEMBER THERE IS NO RIGHT OR WRONG WHEN IT COMES TO TECHNIQUE FOR RECOVERING THIS SEAT, SO DO IT WHICHEVER WAY YOU FIND COMFORTABLE. ALSO THIS IS THE 2ND TIME THAT I HAVE DONE THIS SO FEEL FREE TO COMMENT AND ADD TIPS FOR ANYONE ELSE LOOKING TO TRY THIS.

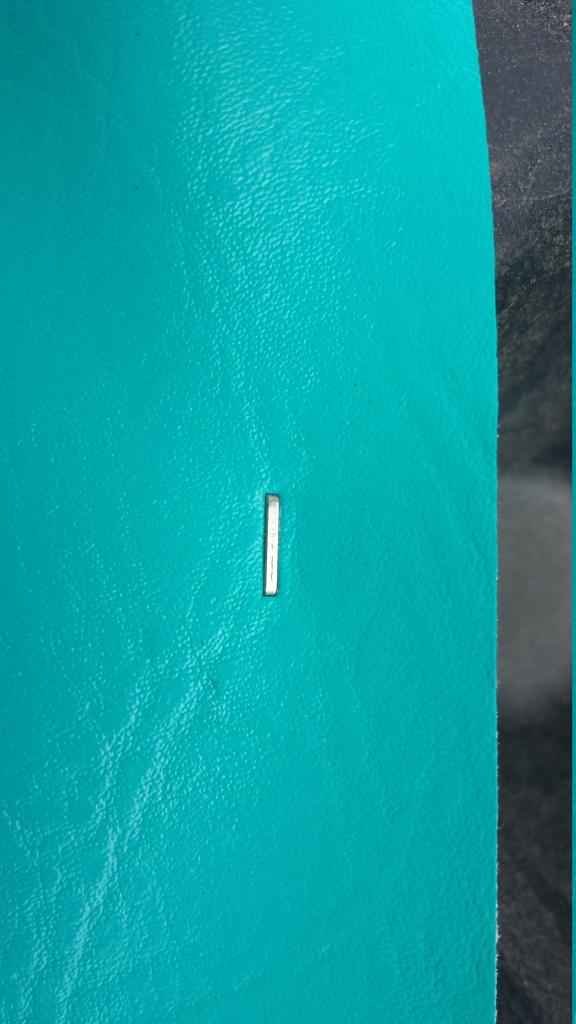

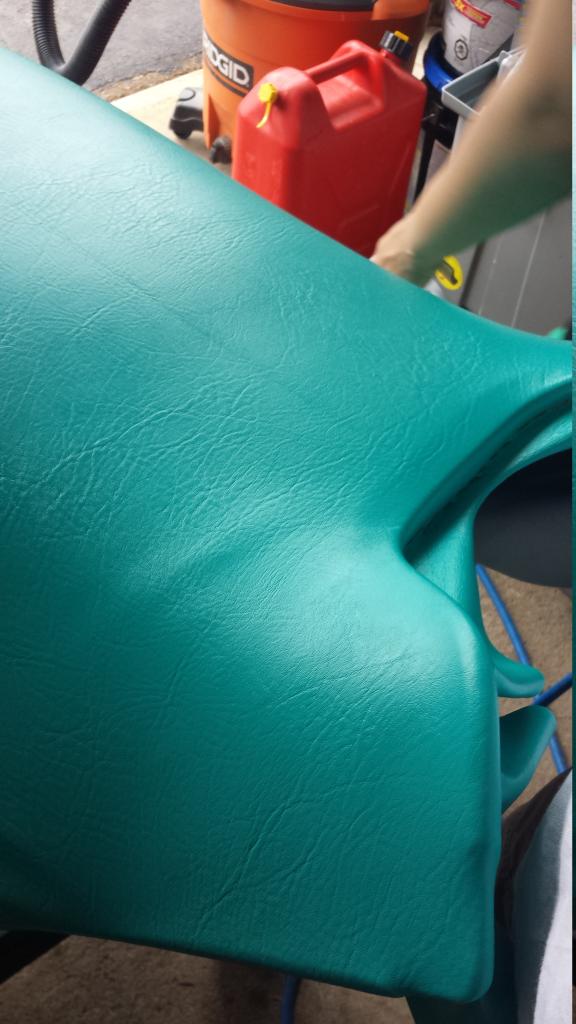

So let’s start off with the seat and existing cover... as you can see it’s a little weathered, and in general it’s time to be replaced.

And the tools that I use to get the job done:

1) ¼” drive ratchet with 10mm socket and 3” extension

2) ¼” drive ratchet with 4mm Allen head socket

3) No.1 (Green) Robertson screw driver, and some assorted flat screw drivers(for prying)

4) Pneumatic Stapler and some Stainless staples

5) A knife of some sort, I used a razor blade because it’s extremely sharp and worked well for me.

6) A container to hold misc fasteners and parts that you remove from the seat that you need to reinstall after the seat is recovered.

OK ... Let’s get started!

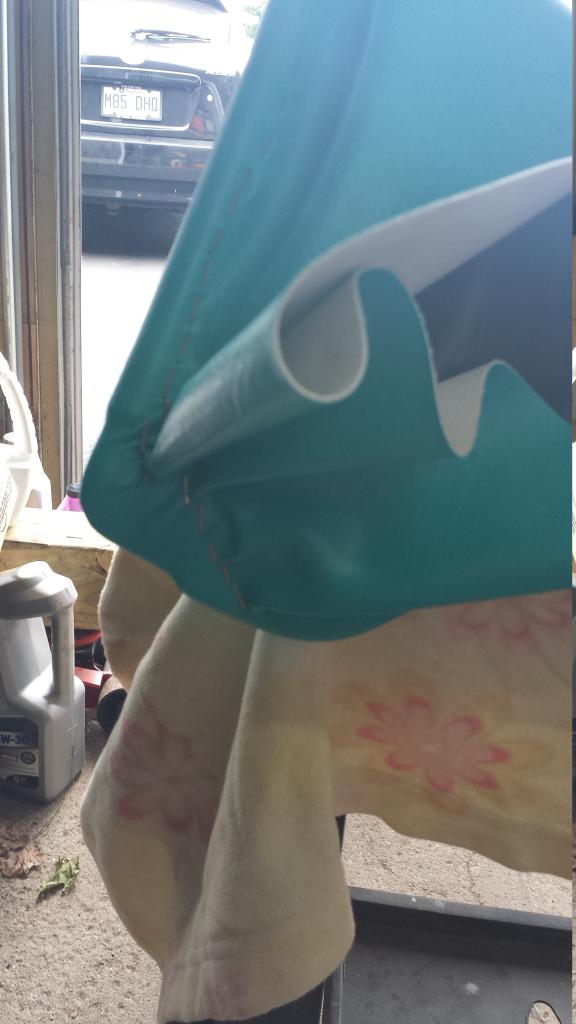

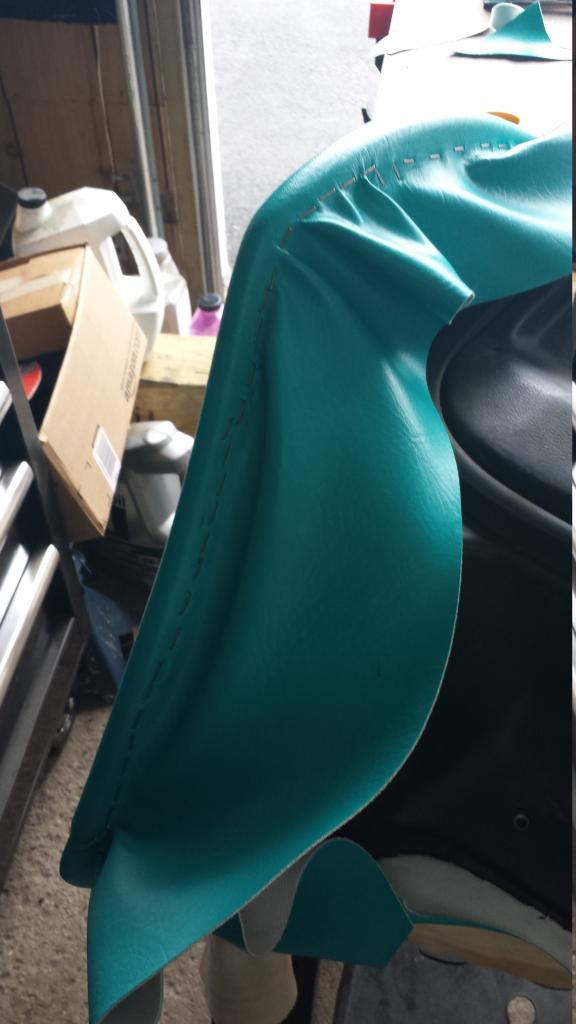

Step 1: Place the new cover in the sun to warm it up and make it easier to stretch it over the foam and seat base, I do this first so it has a chance to heat up while I remove the old cover and prep the base. Remove all of the screws and attachment clips from the back side of the seat.

You also want to remove the strap, this is done with the 4mm Allen head socket.

When I was rebuilding a 1994 SPI for my girlfriend I needed to recover the seat, well in my search to find a “How To” on the subject, I came up empty. So I figured I would write my own when it came time to recover my SPX seat.

DISCLAIMER: THIS IS THE WAY THAT I FOUND WORKED BEST FOR ME, THERE IS VIRTUALLY 100 PLUS WAYS TO DO THIS, SO WHAT EVER WAY YOU FIND WORKS BEST FOR YOU IS THE WAY THAT YOU WILL WANT TO DO THIS. REMEMBER THERE IS NO RIGHT OR WRONG WHEN IT COMES TO TECHNIQUE FOR RECOVERING THIS SEAT, SO DO IT WHICHEVER WAY YOU FIND COMFORTABLE. ALSO THIS IS THE 2ND TIME THAT I HAVE DONE THIS SO FEEL FREE TO COMMENT AND ADD TIPS FOR ANYONE ELSE LOOKING TO TRY THIS.

So let’s start off with the seat and existing cover... as you can see it’s a little weathered, and in general it’s time to be replaced.

And the tools that I use to get the job done:

1) ¼” drive ratchet with 10mm socket and 3” extension

2) ¼” drive ratchet with 4mm Allen head socket

3) No.1 (Green) Robertson screw driver, and some assorted flat screw drivers(for prying)

4) Pneumatic Stapler and some Stainless staples

5) A knife of some sort, I used a razor blade because it’s extremely sharp and worked well for me.

6) A container to hold misc fasteners and parts that you remove from the seat that you need to reinstall after the seat is recovered.

OK ... Let’s get started!

Step 1: Place the new cover in the sun to warm it up and make it easier to stretch it over the foam and seat base, I do this first so it has a chance to heat up while I remove the old cover and prep the base. Remove all of the screws and attachment clips from the back side of the seat.

You also want to remove the strap, this is done with the 4mm Allen head socket.

Last edited by a moderator: