Iceman2017

Member

So I've got twin 717 in a 2000 Challenger. I've done everything carefully and by the book, rebuilt both carbs, replaced oil filter, replaced fuel\water separators, wear rings are new, impellers are good, and have fresh gas. Been running GREAT...:until yesterday!

I sucked up a TON of weeds and overheating alarm was going off loud...I'm really hoping I didn't fry anything but since I know nearly nothing about the actual engine I thought I'd see what you guys know...when I got it on the trailer the one engine would start but die immediately when given gas and wouldn't go above 1500rpm.

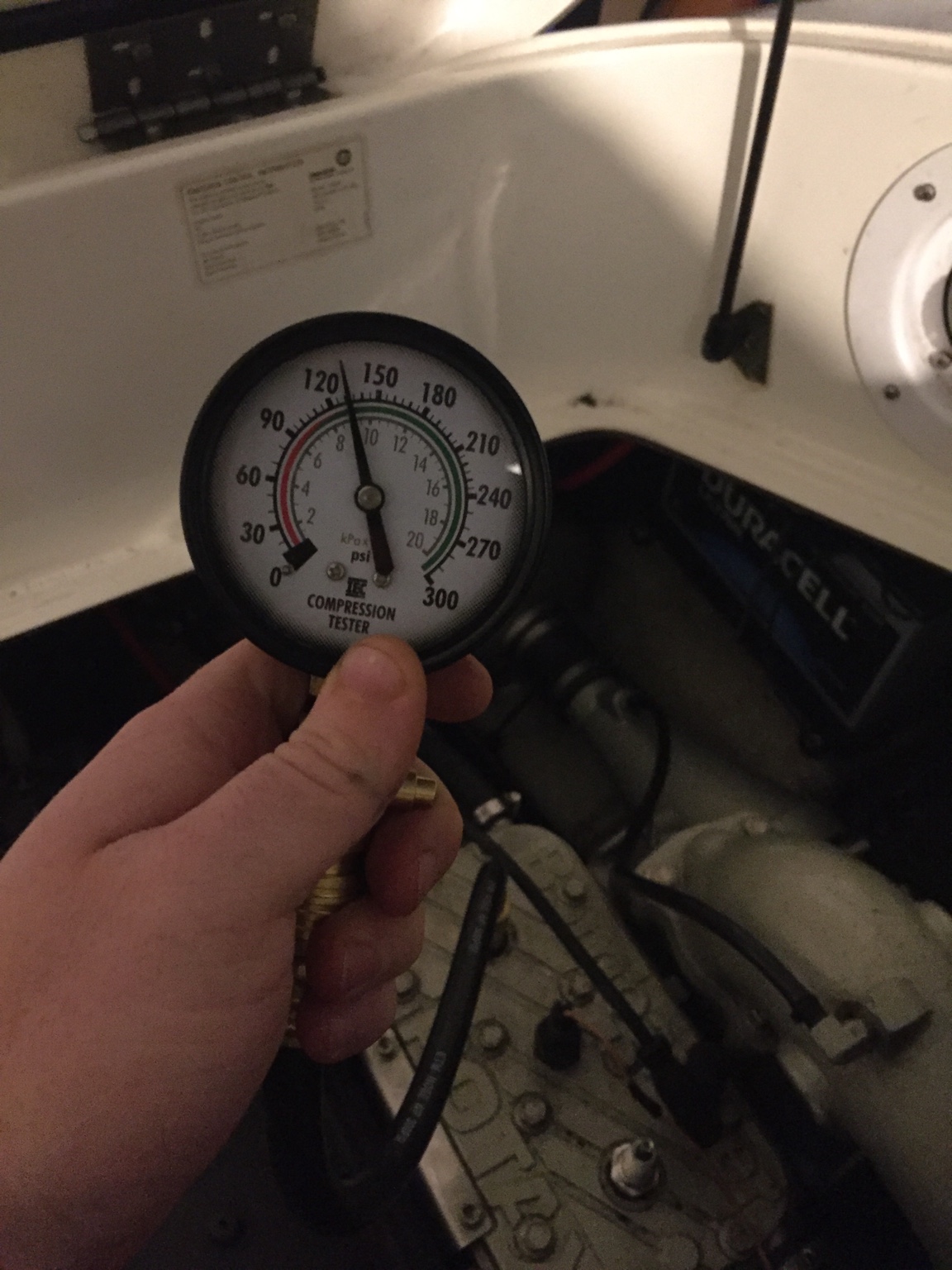

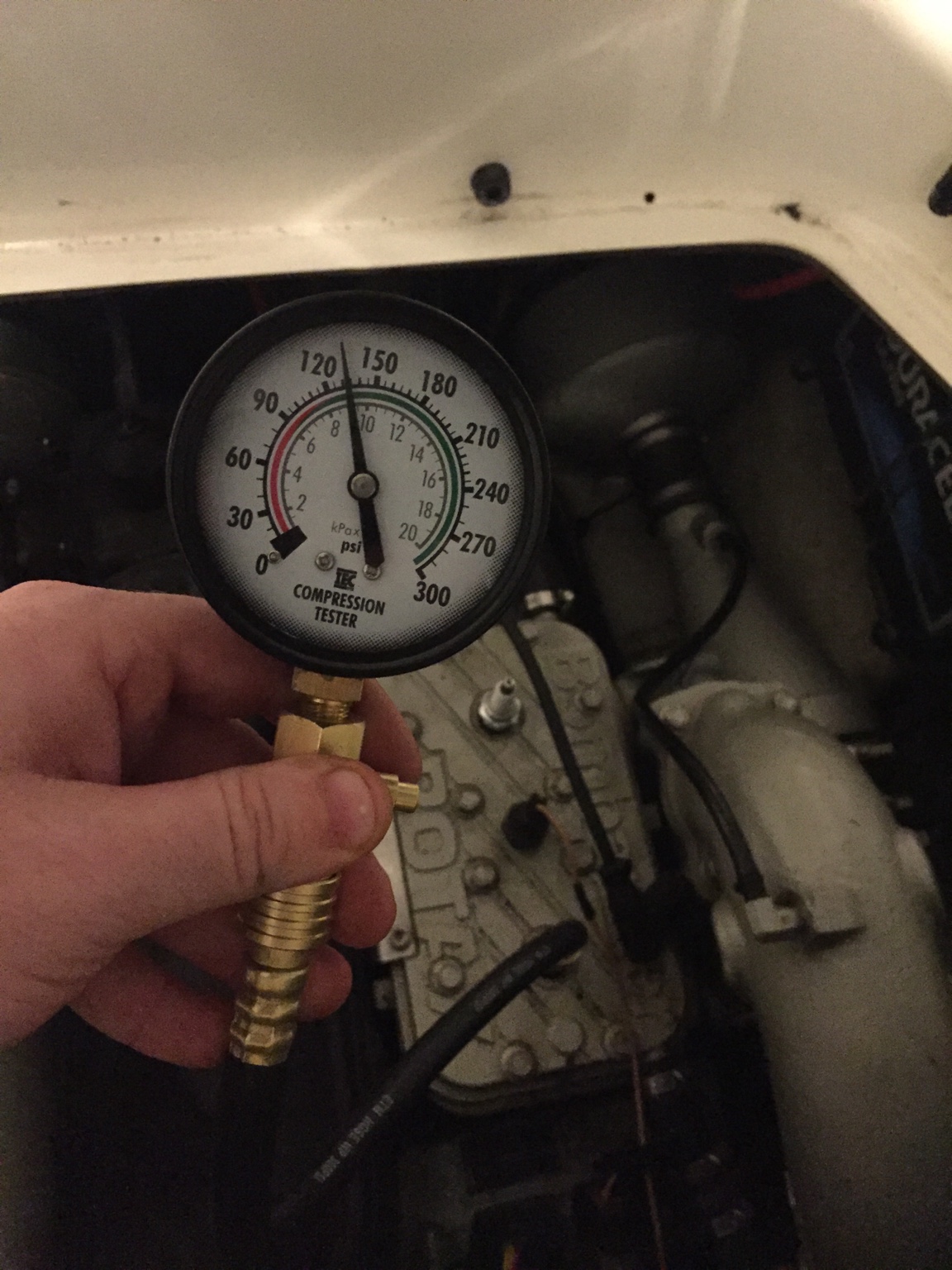

I went in with a borescope through the spark plug holes and the attached photos are of the top of the positions looking down. Is the black looking stuff normal or did I ruin my pistons??? Anyfeeeback is greatly appreciated. Also compression is 130 on both pistons(using a cheap $25 checker from amazon) SEE PHOTOS, thank you!

And other piston from other spark hole:

I have a video of the borescope of anyone is interested or if it would make any difference in diagnosis. Thank you all very much for any help or advice.

Last edited by a moderator: