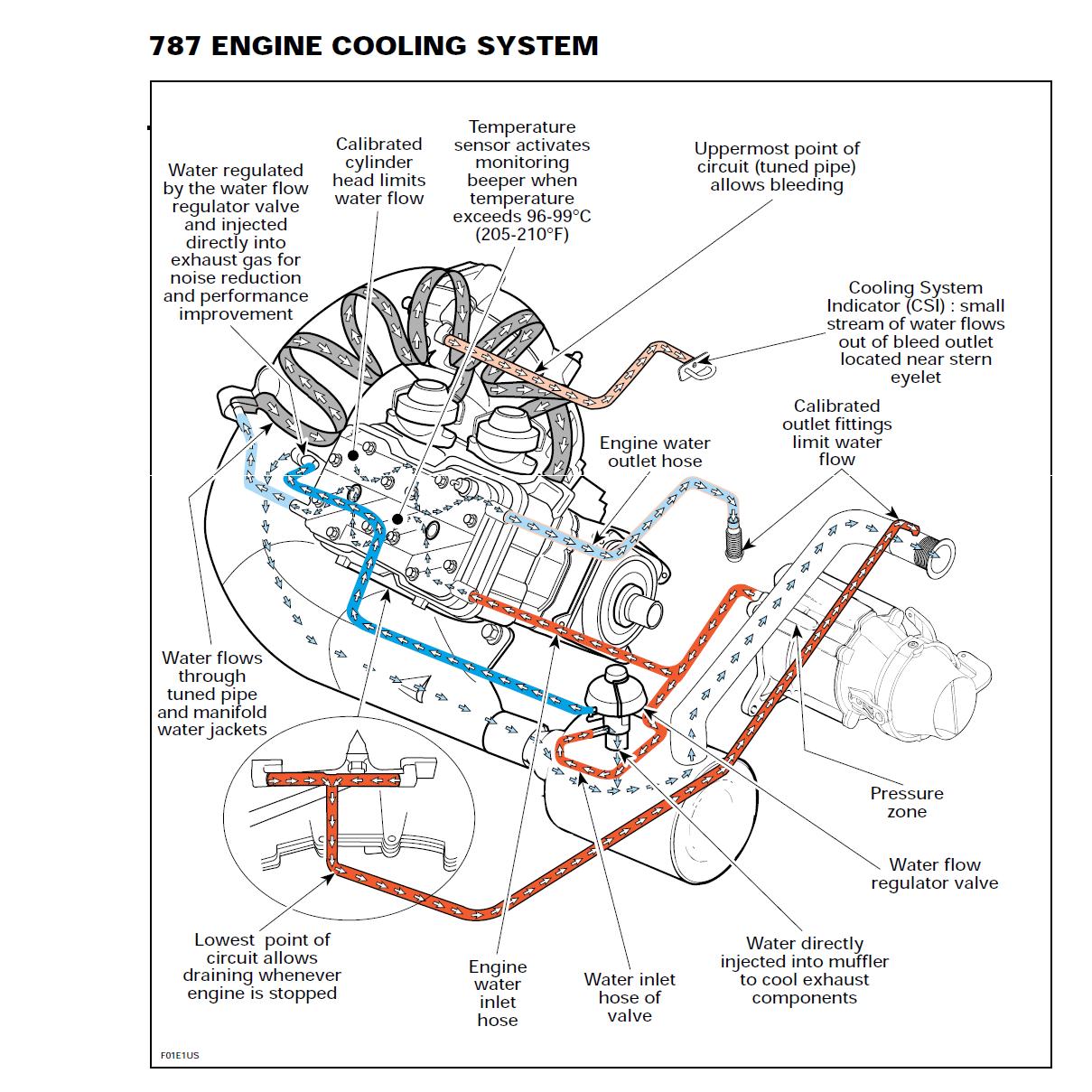

my use of the term "Pump" was referring to the engines existing Water Pumps....not the propulsion unit.

Yes, the jet pump is also responsible for producing the pressurized cooling water supply so there is only one pump on the entire system. Aside from the bilge pump, that is.

Aside joke FWIW, a very leaky boat is sometimes called a bilge recirculation pump, as opposed to a bilge pump. (get the joke?)

Anyway, RacerXX just provided the diagram you seek, it's a once through cooling system and there is no recirculation pump such as can be found on a Mercruiser stern drive system, for instance. In the case of a Mercruiser, a closed-loop coolant setup is possible due to the engine-driven recirculation pump. It's possible but not advisable to eliminate the Mercruiser recirculation pump thus converting the Mercruiser into a once-through system similar to the Seadoo.

Neither of these systems are terribly complex once you become familiar, remember though these engines produce insane amounts of heat that must be carried away, a low power bilge pump wouldn't come close to providing enough flow to compensate while underway.

Back in the day, we used to place a scoop pickup under the "race" boat hull and this provided the cooling water supply only as the boat was moving, and in most cases an engine-driven recirculation pump to keep water moving through the block but using this system at low/no speed or stopped, the engine didn't receive enough supply of cold water for adequate cooling. These boats didn't have reverse at the time, either! :O

So here's the basic diagram of a raw-water cooled Mercruiser which does use an engine driven recirculation pump for comparison, you can see the differences AND I bet you can guess where the system could be isolated and heat exchanger would be inserted: