Hey guys,

Merry Christmas! I purchased a very neglected 2000 Challenger 2000 last year and have completely restored it. It showed almost zero salt water use ( I live and purchased it in Florida). I had to reinstall intake manifold, fuel pump (replaced pump in vapor separator). The engine has compression of 121psi on all cylinders (different gauge showed a little higher).

I had everything back together and it started great and idled perfectly for miles on the water, however it was covering the plugs with black oil / soot. I converted this engine to premix while I had everything apart and ran it a 50:1.

After the engine warmed up, I gave it throttle and as soon as the butterfly valves on the manifold opened, it would bog and die unless I closed the throttle back to zero.

I replaced the trigger as the wires were frayed and made sure the stator was in working order. As mentioned earlier, it starts very fast and will idle nicely (even though the tach is running about 3-4k rpms too high??) The voltage regulators are showing 14.2 at fast idle.

I then tested the TPS after unhooking the working port sensor and I was able to get the voltage to .15-.20 volts. WOT voltage on the sensor was only 3.3v.

Just for kicks I unplugged the throttle sensor and the boat would run very rich at idle but it was able to accelerate ( I didn't open it up very much)..The boat now runs with the throttle plates partially open. The TPS disconnected make a immediate difference in allowing the boat to take SOME throttle (smoky but no surging). Also, I cleaned all filters and have 34psi when running. Port side cylinders seem to have a little less soot on them when reading plugs.

I'm going to purchase the Candoo Mercury Tool to help solve a lot of common issues that these boats have. I hope to offer insight to the forum as I learn more about how to use the tool.

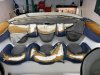

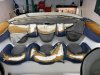

While I wait for the tool, does anyone have any ideas on why disconnecting the TPS sensor allowed the boat to accelerate ( Tach is running very high for some reason so I don't know how many RPMS I was running at). I have attached some Pics of this boat transformation.. I previously had a 2003 Challenger X with the 250 opti. It ran great but had a weak hull (bad hull)... This boat is solid but needs some tweaking on the engine..

Thanks again!

Joe

Merry Christmas! I purchased a very neglected 2000 Challenger 2000 last year and have completely restored it. It showed almost zero salt water use ( I live and purchased it in Florida). I had to reinstall intake manifold, fuel pump (replaced pump in vapor separator). The engine has compression of 121psi on all cylinders (different gauge showed a little higher).

I had everything back together and it started great and idled perfectly for miles on the water, however it was covering the plugs with black oil / soot. I converted this engine to premix while I had everything apart and ran it a 50:1.

After the engine warmed up, I gave it throttle and as soon as the butterfly valves on the manifold opened, it would bog and die unless I closed the throttle back to zero.

I replaced the trigger as the wires were frayed and made sure the stator was in working order. As mentioned earlier, it starts very fast and will idle nicely (even though the tach is running about 3-4k rpms too high??) The voltage regulators are showing 14.2 at fast idle.

I then tested the TPS after unhooking the working port sensor and I was able to get the voltage to .15-.20 volts. WOT voltage on the sensor was only 3.3v.

Just for kicks I unplugged the throttle sensor and the boat would run very rich at idle but it was able to accelerate ( I didn't open it up very much)..The boat now runs with the throttle plates partially open. The TPS disconnected make a immediate difference in allowing the boat to take SOME throttle (smoky but no surging). Also, I cleaned all filters and have 34psi when running. Port side cylinders seem to have a little less soot on them when reading plugs.

I'm going to purchase the Candoo Mercury Tool to help solve a lot of common issues that these boats have. I hope to offer insight to the forum as I learn more about how to use the tool.

While I wait for the tool, does anyone have any ideas on why disconnecting the TPS sensor allowed the boat to accelerate ( Tach is running very high for some reason so I don't know how many RPMS I was running at). I have attached some Pics of this boat transformation.. I previously had a 2003 Challenger X with the 250 opti. It ran great but had a weak hull (bad hull)... This boat is solid but needs some tweaking on the engine..

Thanks again!

Joe