If anyone has a thread or doc on how to replace the "hull thru fitting" on a 97 challenger 1800, it would be greatly appreciated.

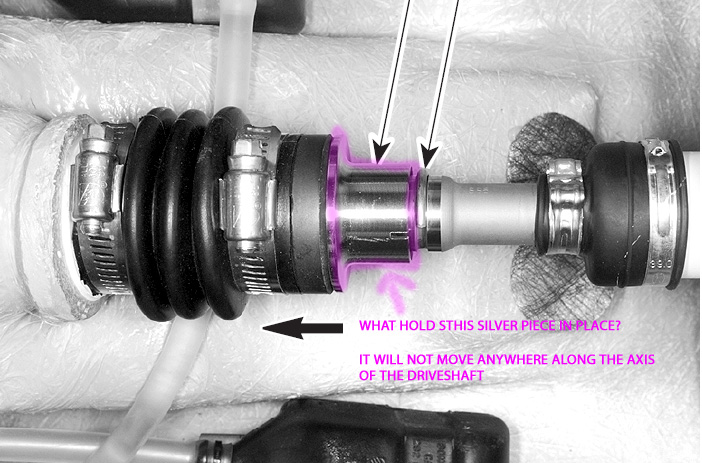

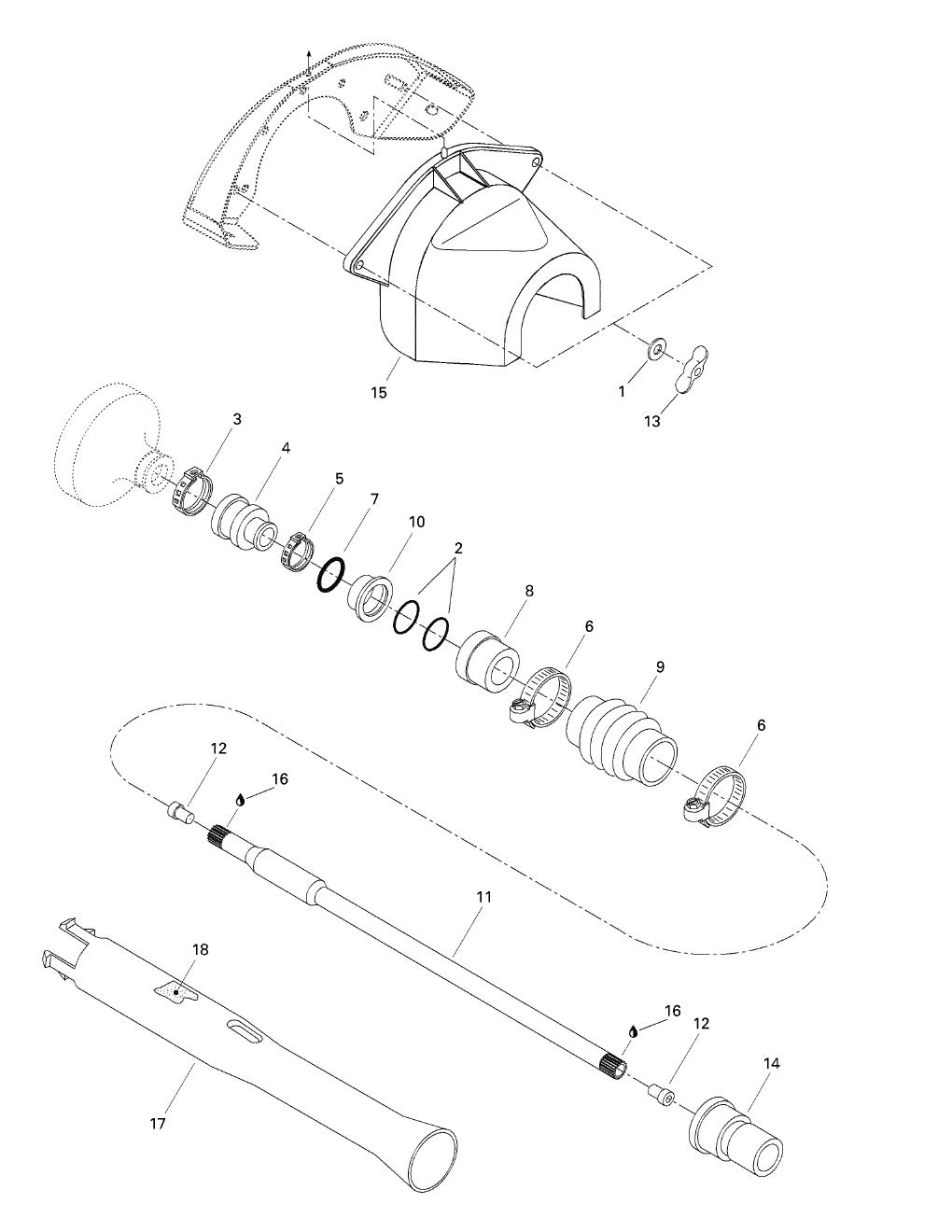

I originally thought my problem was from the infamous carbon ring so I bought one and the two o-rings and began following the super description on this site about how to do it. All went well until I took the old carbon ring out and measured it and direct compared it to the new one but there was zero difference so I took the accordion boot off too, sure enough my HTF is toast.

I am going to pickup a new one from brp tomorrow AM but I thought I'd get ahead of the game by removing the old one but I don't know if there is a 'good' way and a 'bad' way to get it out.

Any help would be greatly appreciated!

Thanks,

Shawn

I originally thought my problem was from the infamous carbon ring so I bought one and the two o-rings and began following the super description on this site about how to do it. All went well until I took the old carbon ring out and measured it and direct compared it to the new one but there was zero difference so I took the accordion boot off too, sure enough my HTF is toast.

I am going to pickup a new one from brp tomorrow AM but I thought I'd get ahead of the game by removing the old one but I don't know if there is a 'good' way and a 'bad' way to get it out.

Any help would be greatly appreciated!

Thanks,

Shawn