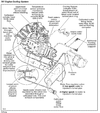

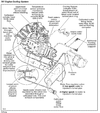

Seems I need a top end on at least 1 motor every season. Running at 7K for 10 min or more consistently requires me to limp back in on 1 motor. Pisser works but don't think am getting enough flow through the cyls at high speed. In reading the flow diagram, below, I see that the water flows into the 3 holes in impeller, through head, pipe, cyls, and finally out through the "T" tube and calibrated outlet fitting in resonator outlet. Am looking to increase water flow through the cyl jackets at high speed. The 3 impeller holes look good and the flow on the hose is more than adequate. Anyone found a way to increase the flow through the cyls or have any ideas? Perhaps recalibrating/enlarging the outlet fitting in the resonator?