cwb449

Member

300hp + 4 tec

Hi everyone,

I have a 2007 RXP 215 that I love dearly but, servicing it out for the summer I found #3 cylinder is only putting out around 65 psi where it should be about 140 psi! Now this is a real bummer for sure!! I really didn't want to rebuild the whole engine, so I checked to see if it might be a valve problem or a ring problem.

I put a shot of 30w engine oil in the cylinder, installed the plug and checked the compression again but very little change...oh boy the rings are shot!!

For me it's a good, bad thing. I've built racing engines for years and think this might be a good opportunity. This will be my 3rd 4 tec engine I've built but, this engine is going to have some SERIOUS muscle behind this hustle.

As always I never do anything halfway, as this will be the case! It's going to take around two to three months for this project and would like to share all my experiences...the good, the bad and the ugly with you folks here on the forum. I will have a lot of questions, hopefully a few answers, and probably a whole lot of head scratching.

I just bought the turbo off of Ebay so you can see (I hope) from the pictures I'm pretty serious about this project. I'm just wondering if I should bore the block out or have #3 cylinder re-sleeved? The other two cylinders are in perfect shape. Myself I would like to bore the block out to 30 over since I'm going to install Riva 8.4 racing pistons anyway. I wonder is 30 over way too much? I want reliability as well as neck breaking performance!! I'd like to know what you think.

It's Saturday morning, time to pull the engine and see what kind of mess I've got. All personal input is more than welcome!!

_______________________________________________________________________________________________________________________

Update; 03/23/10

Hi folks,

Sorry it took so long to update, I've been busy pulling the engine tearing it down and finding out what went wrong....and how to fix it.

I was hoping the ring just gave out but, it's a little worst than that! One of the exhaust valves cracked and the broken pieces hammered the head and the piston causing the failure! As you can see in the pictures;

I haven't had a chance to pull the valve to what kind of damage was done to the valve seat but I'm sure it's not good!

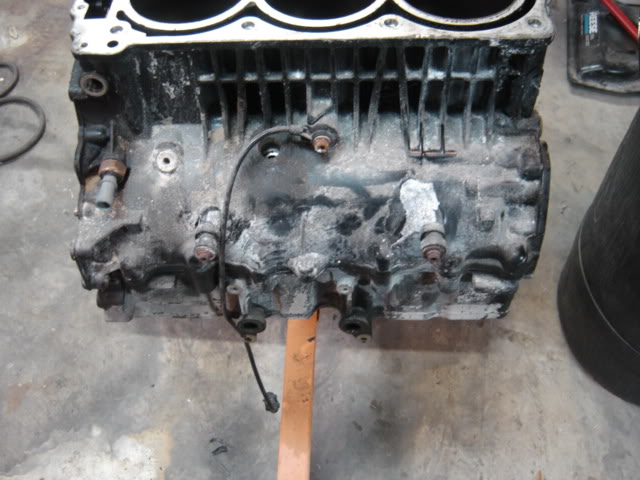

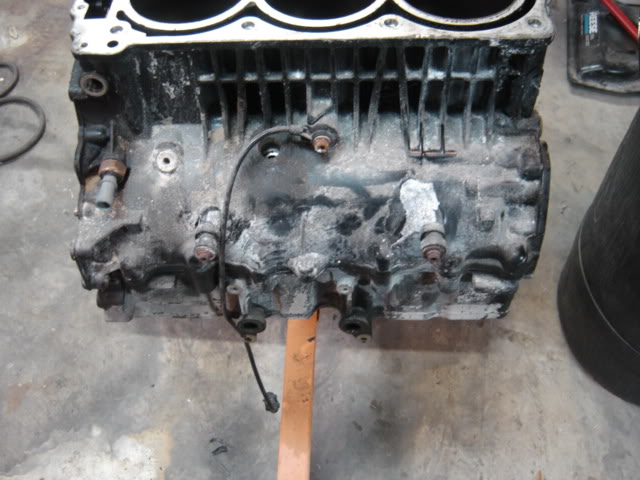

I hope I don't have to get a new head! It's going to be expensive as it is but... I got to do what I've gotta do... to make matters worse the block looks really bad!! It's amazing what salt water can do!! There is no way I'm going to an rebuild an engine that looks like this! Check out these pictures:

It looks like I'm going to be doing soon serious glass beading and powder coating!!

Well heck, until I can figure out what I'm going to do about the engine, I guess it's time to flip the Sea Doo up side down and start blueprinting the bottom hull.

Folks, I do want you to know that about 90% of this work is going to be done in my garage (I hope), and that this is very important to me that you folks know this, I'm just a backyard mechanic, that really enjoys what I do and has an understanding wife that supports my passion... okay I was told to put that in there!!! Just kidding...NOT...lol!

I want to thank everyone who responded and hope to see a lot more imput and support. If you have any questions, please feel free to ask.

Until next update,

Curtis aka cwb449

Hi everyone,

I have a 2007 RXP 215 that I love dearly but, servicing it out for the summer I found #3 cylinder is only putting out around 65 psi where it should be about 140 psi! Now this is a real bummer for sure!! I really didn't want to rebuild the whole engine, so I checked to see if it might be a valve problem or a ring problem.

I put a shot of 30w engine oil in the cylinder, installed the plug and checked the compression again but very little change...oh boy the rings are shot!!

For me it's a good, bad thing. I've built racing engines for years and think this might be a good opportunity. This will be my 3rd 4 tec engine I've built but, this engine is going to have some SERIOUS muscle behind this hustle.

As always I never do anything halfway, as this will be the case! It's going to take around two to three months for this project and would like to share all my experiences...the good, the bad and the ugly with you folks here on the forum. I will have a lot of questions, hopefully a few answers, and probably a whole lot of head scratching.

I just bought the turbo off of Ebay so you can see (I hope) from the pictures I'm pretty serious about this project. I'm just wondering if I should bore the block out or have #3 cylinder re-sleeved? The other two cylinders are in perfect shape. Myself I would like to bore the block out to 30 over since I'm going to install Riva 8.4 racing pistons anyway. I wonder is 30 over way too much? I want reliability as well as neck breaking performance!! I'd like to know what you think.

It's Saturday morning, time to pull the engine and see what kind of mess I've got. All personal input is more than welcome!!

_______________________________________________________________________________________________________________________

Update; 03/23/10

Hi folks,

Sorry it took so long to update, I've been busy pulling the engine tearing it down and finding out what went wrong....and how to fix it.

I was hoping the ring just gave out but, it's a little worst than that! One of the exhaust valves cracked and the broken pieces hammered the head and the piston causing the failure! As you can see in the pictures;

I haven't had a chance to pull the valve to what kind of damage was done to the valve seat but I'm sure it's not good!

I hope I don't have to get a new head! It's going to be expensive as it is but... I got to do what I've gotta do... to make matters worse the block looks really bad!! It's amazing what salt water can do!! There is no way I'm going to an rebuild an engine that looks like this! Check out these pictures:

It looks like I'm going to be doing soon serious glass beading and powder coating!!

Well heck, until I can figure out what I'm going to do about the engine, I guess it's time to flip the Sea Doo up side down and start blueprinting the bottom hull.

Folks, I do want you to know that about 90% of this work is going to be done in my garage (I hope), and that this is very important to me that you folks know this, I'm just a backyard mechanic, that really enjoys what I do and has an understanding wife that supports my passion... okay I was told to put that in there!!! Just kidding...NOT...lol!

I want to thank everyone who responded and hope to see a lot more imput and support. If you have any questions, please feel free to ask.

Until next update,

Curtis aka cwb449

Last edited by a moderator: