-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2003 sportster 155 4-tech

- Thread starter jhaase

- Start date

- Status

- Not open for further replies.

We recently purchased a 2003 sportster 4-tech 155. It is having a cavitation problem. We replaced the wear ring and sealed everything with silicon. It still has the problem. We noticed the 4 screws are missing that hold the wear ring in place. Could that cause cavitation?

The cause could be the carbon seal. When the seal or the parts that touch the seal need service the seal allows air to pass through it from within the hull. Once it passes through the seal it goes directly to the impeller.

Normally the seal will leak water as well. So, have you notice more than normal water in the hull?

This is our first boat so I am not sure what normal water leakage would be. We did not leave it in the water long do to cavitation. How do I tell if the seal is bad? We did check it out and nothing looks wrong with it but we do not really know what to look for as far as if it is good or bad.

Have you had a Seadoo ski before by chance? If so, the seal is the same. I would recommend downloading a manual due to your limited knowledge. It will help you a ton. I'll post a pic of the seal, but unless you know what you are after this could get challenging. The seal is designed to leak. But we are talking drips,, It does this to cool it self as well as lubricate itself. If a stream of water is coming in, it is defective or the bellows are or the O-ring holding the collar has failed.

Last edited by a moderator:

I had Polaris before the Seadoo's I own now. They were good skis. Sold them simply because of age.

Repairing and selling iPads, iPhones and Mini iPads.

Repairing and selling iPads, iPhones and Mini iPads.

We had a carb issue and kept melting pistons. Could not get them set right on one ski. The other was great no problems. So we decided to go with a 4 stoke thinking it is a better motor. The seadoo ski we have now is a 2 stroke but at least with a seadoo there are still shops around here that work on them so if we have trouble we can get local help.

The 4-tec engines are well proven. Really like the ease of riding them.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

pwgsx

Well-Known Member

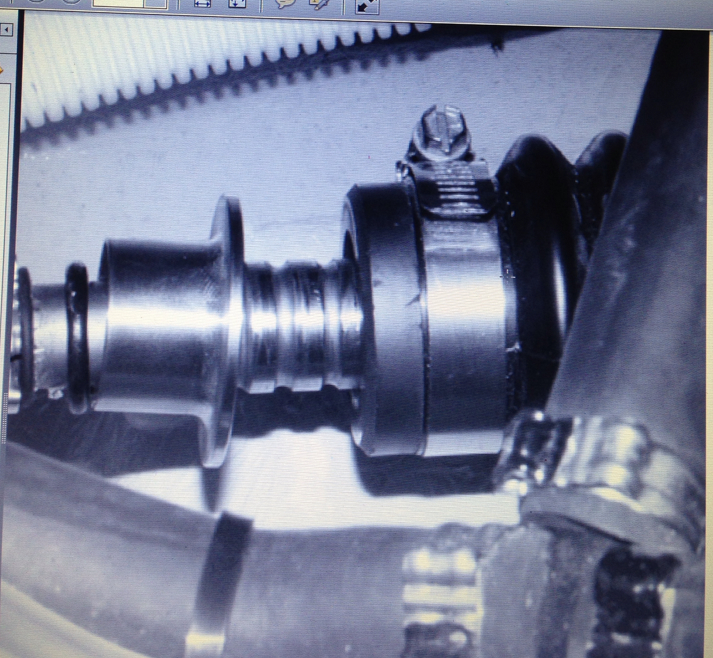

The screws hold it from spinning in the plastic pumps but I doubt that would be causing your issue but you want to fix that. How much space do you have between the wear ring and impeller? Also you can undo the clamp holding the black bellow and carbon ring and push it towards the engine a bit and add a large zip tie and re-clamp. This will put more pressure on the carbon ring so if your problem clears up you know your ring is leaking. See pic- the clamp you undo is in red and you put the zip tie right where that brown o ring is. Ignore the o ring though, I thought ahead and that would be used like the zip tie if I ever needed it.

Attachments

Everyone I know of has one at both ends.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

I'd have to look at the specs. You could be correct. I assumed both ends as I have never seen otherwise.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

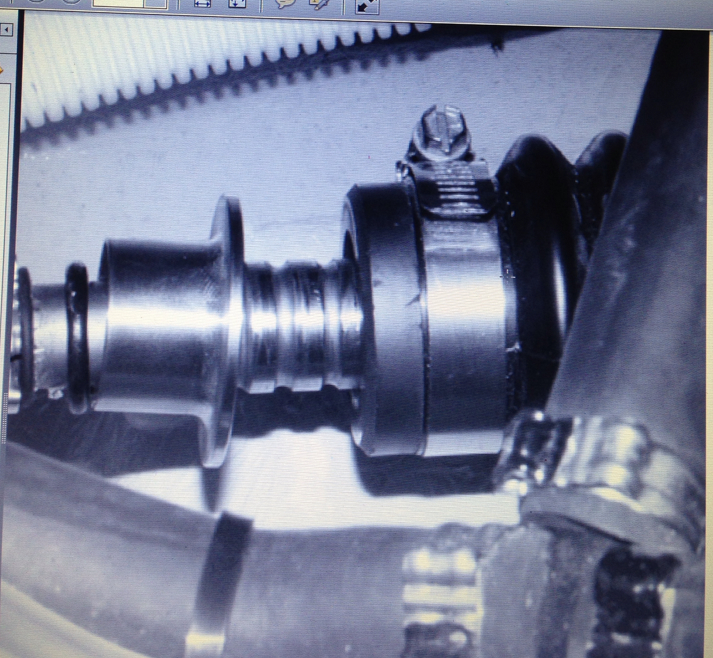

I have a 2003 Sportster that I bought new. It always cavitated. I finally decided to work on it to solve the problem. When I pulled the pump off for inspection I noticed the impeller was sticking out further than the liner This was a factory defect from seadoo.

After some machine work on the housing and machining a new liner out of bronze with minimal clearance between the impeller and the liner my problem was solved. Zero cavitation and 100% better holeshot.

After some machine work on the housing and machining a new liner out of bronze with minimal clearance between the impeller and the liner my problem was solved. Zero cavitation and 100% better holeshot.

Last edited by a moderator:

- Status

- Not open for further replies.

Similar threads

- Replies

- 1

- Views

- 154

- Replies

- 12

- Views

- 281

- Replies

- 4

- Views

- 179

- Replies

- 1

- Views

- 303