Howdy! Recovering stand-up pilot, new Sea-Doo owner & new to the forum.

At first glance perusing the forums, I got the wrong ones - (2) 2001 GTX DI's, one running, one not, with newer trailer. But the price was right (so I think today).

I'm sure there are plenty of threads about pulling the motor out of a GTX DI, I just haven't found the correct "search" for it. Does anyone know of a good link describing the sequence of removal?

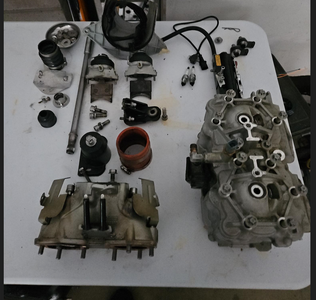

The short of it, the non-running one has 20 lbs of compression in the rear cylinder, 75 lbs front. It has 185 hours on it, rumor is the bottom end is good for 200; thought I'd pull the motor and rebuild it over the winter. Shy of owning a machine shop, my skills are solid enough to do this (have rebuilt a couple of Kawi JS650's and several vehicle engines).

Being an old stand-up owner and knowing what its inner workings look like, my mind was about blown when I saw all the monkey workings in the GTX DI - there's a bit more going on here; I'm sure it will all make sense soon enough.

Anyway, thanks in advance for any guidance and taking the time to read this.

Cheers!

At first glance perusing the forums, I got the wrong ones - (2) 2001 GTX DI's, one running, one not, with newer trailer. But the price was right (so I think today).

I'm sure there are plenty of threads about pulling the motor out of a GTX DI, I just haven't found the correct "search" for it. Does anyone know of a good link describing the sequence of removal?

The short of it, the non-running one has 20 lbs of compression in the rear cylinder, 75 lbs front. It has 185 hours on it, rumor is the bottom end is good for 200; thought I'd pull the motor and rebuild it over the winter. Shy of owning a machine shop, my skills are solid enough to do this (have rebuilt a couple of Kawi JS650's and several vehicle engines).

Being an old stand-up owner and knowing what its inner workings look like, my mind was about blown when I saw all the monkey workings in the GTX DI - there's a bit more going on here; I'm sure it will all make sense soon enough.

Anyway, thanks in advance for any guidance and taking the time to read this.

Cheers!