hotrodssnova

Member

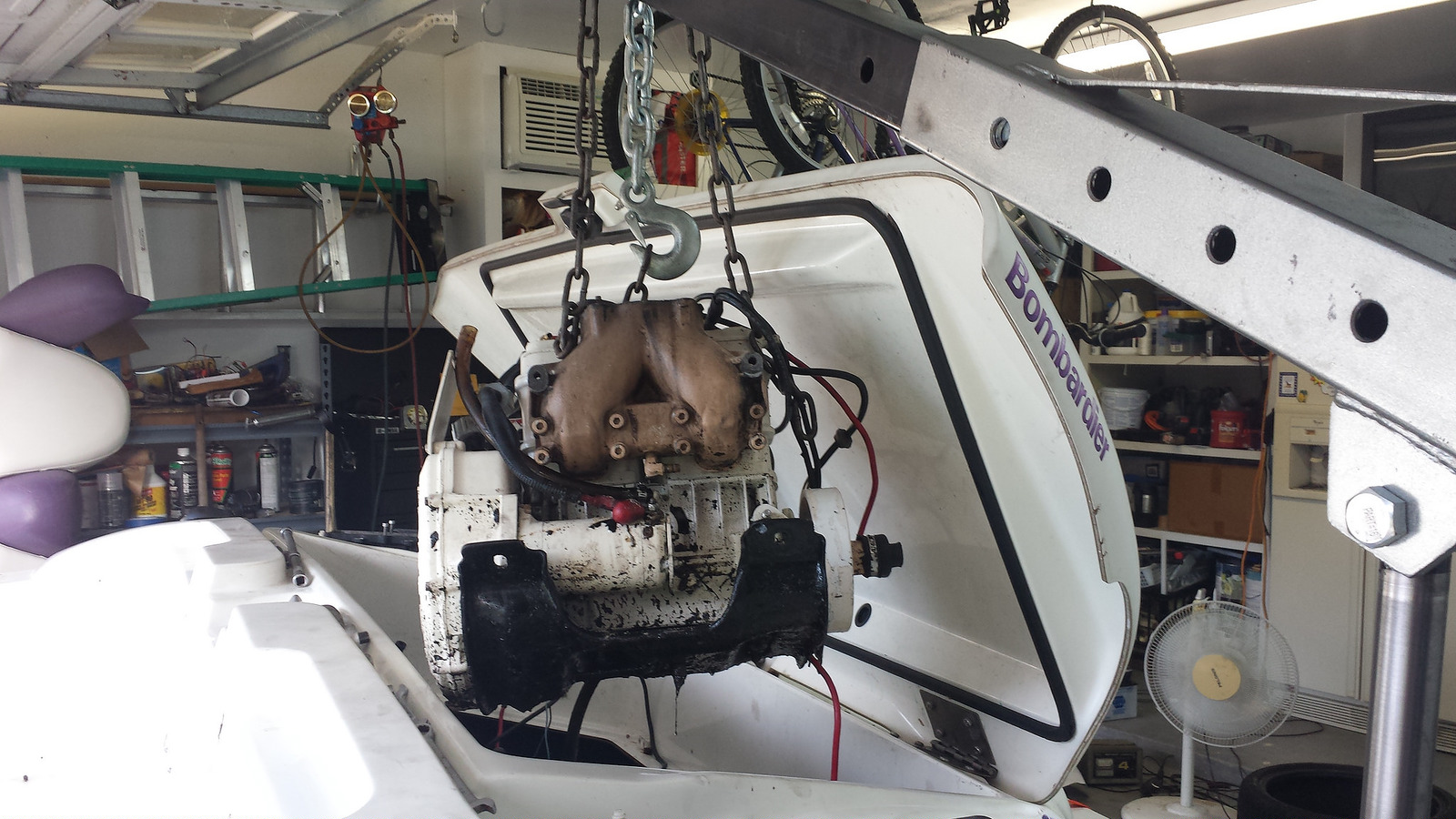

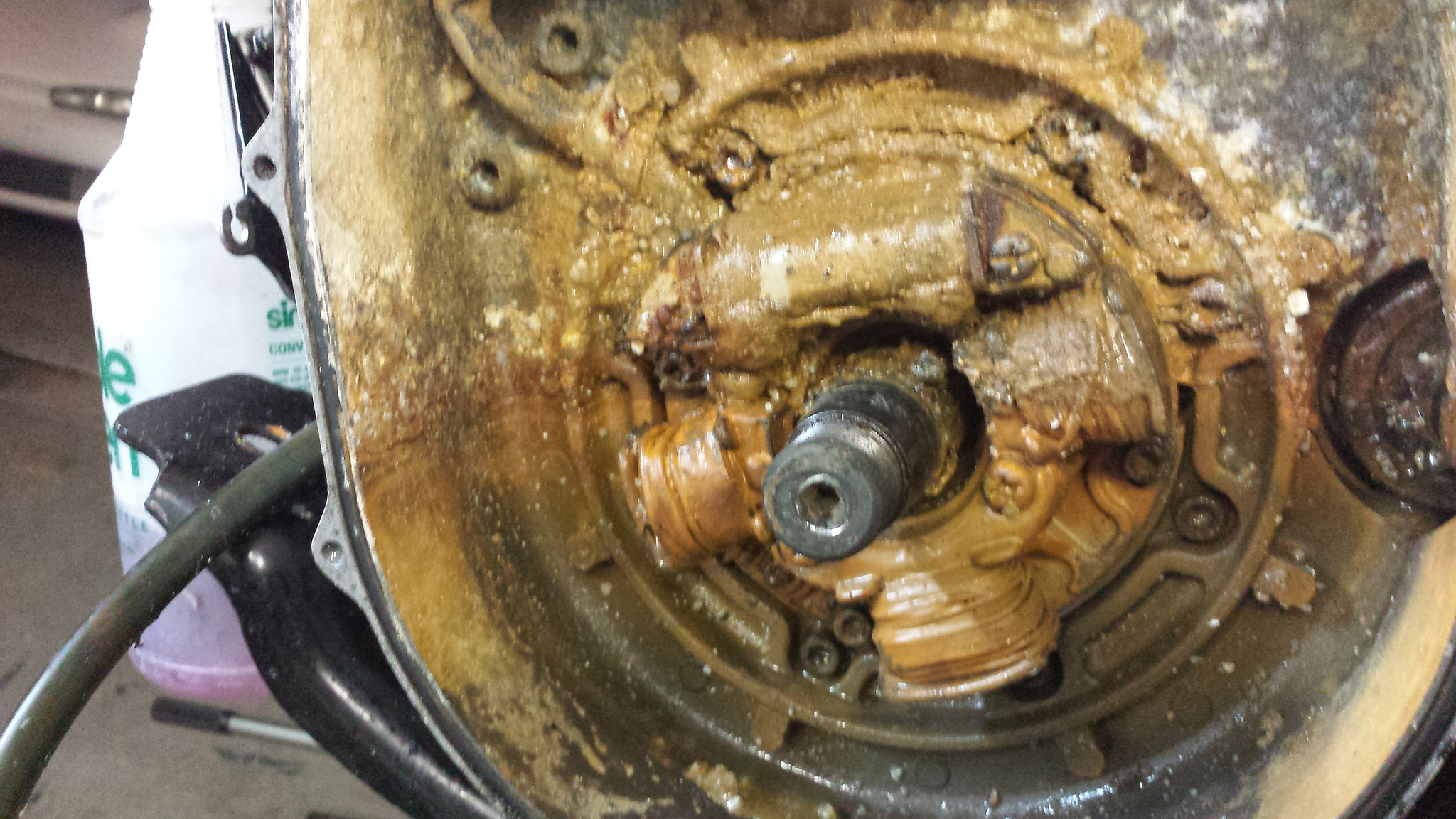

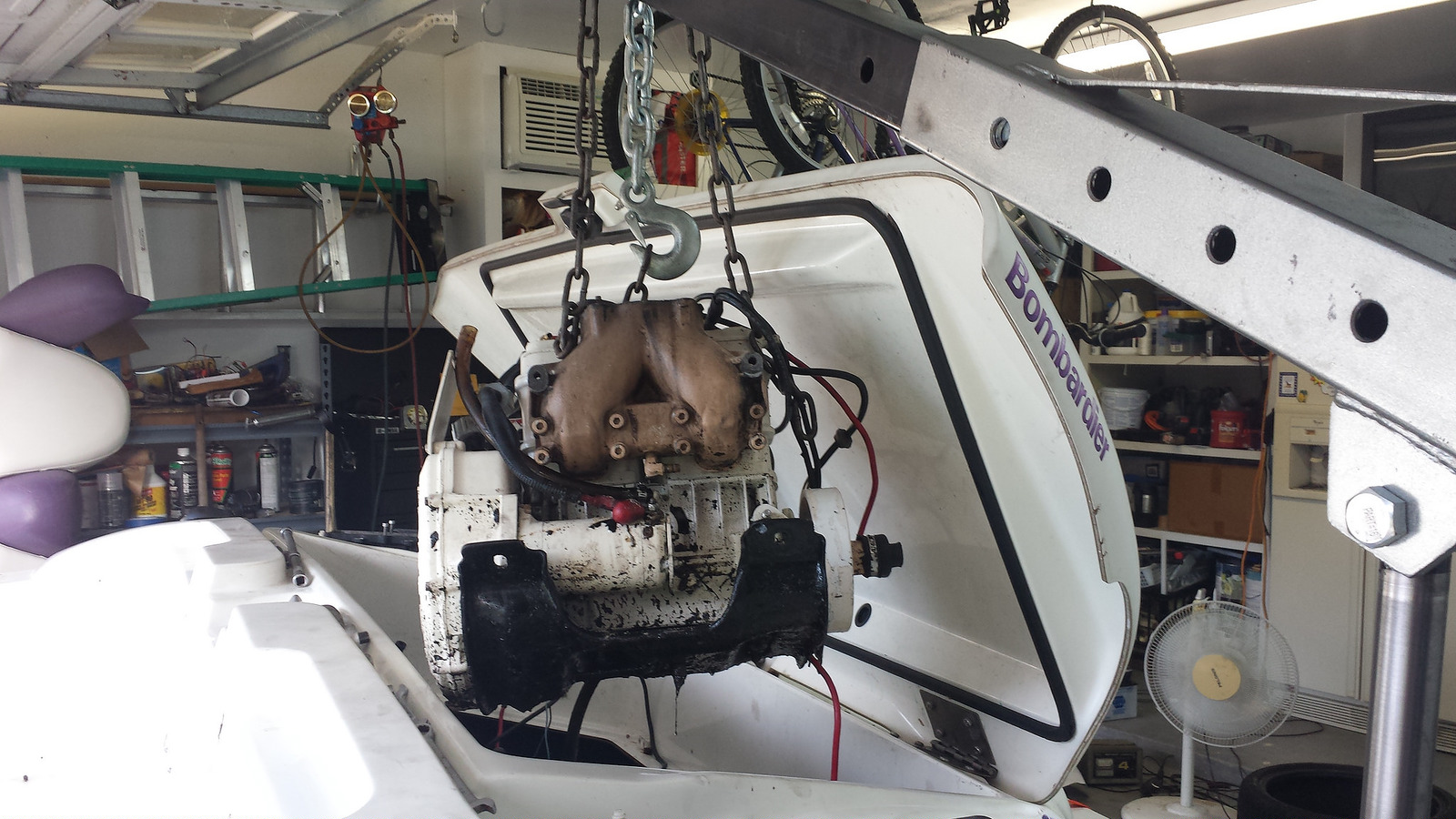

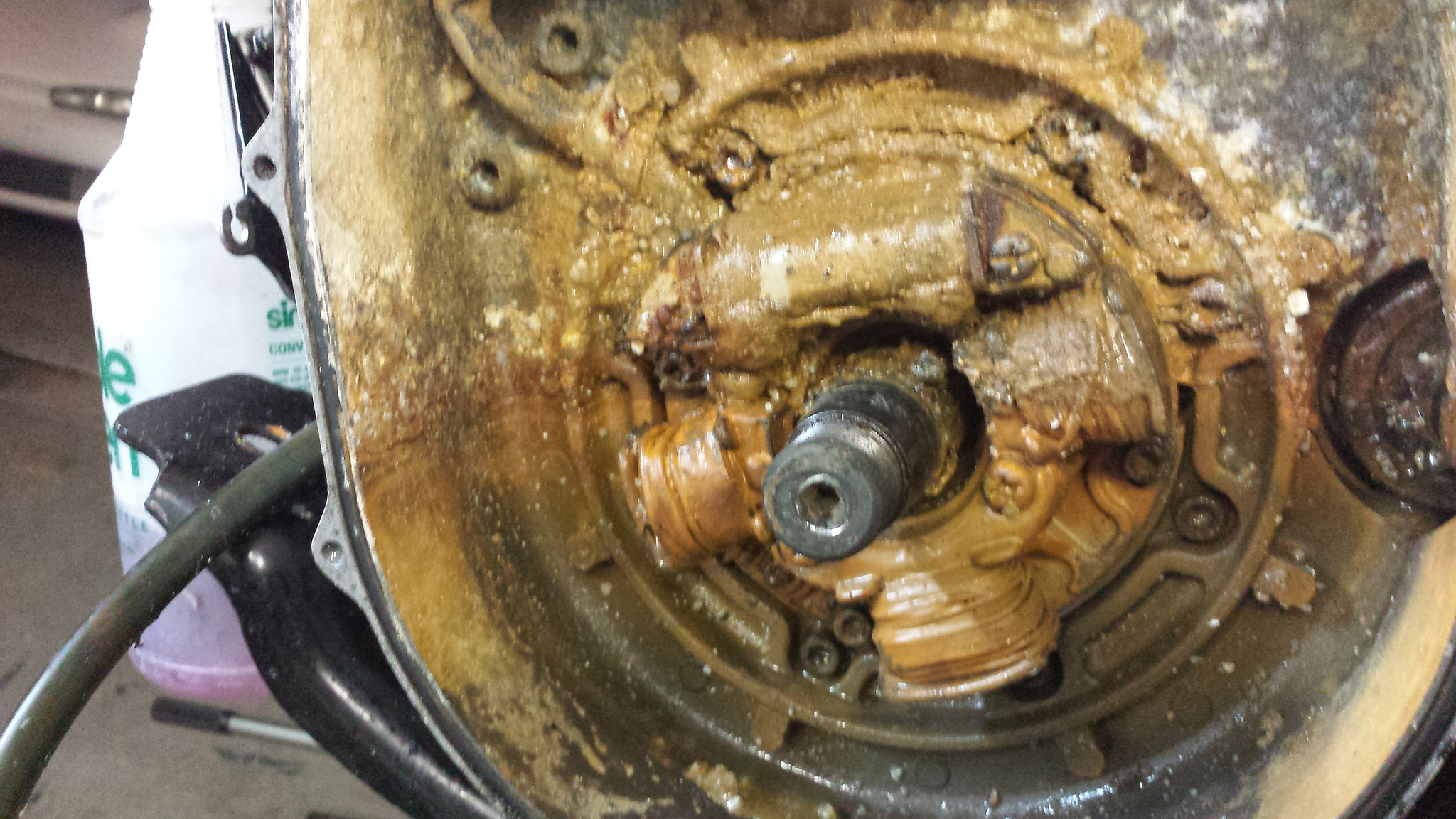

Hi there from Houston! I bought this boat in July. It hasn't run at all this season due to some wiring issues, bad mpem and bad stator. It has twin 657x rotax units. The port side engine has been replaced with a sbt engine, rebuilt carbs and now a new stator. Compression is good at 153 and 148 iirc. I pulled the engine out to replace the stator. Once out I pulled the stator cover and found that it was full of water and had corroded the wiring in the housing and the stator. It tested bad in the boat and needed replaced. I found a loose starter bolt and I think that is where the water got into the case. I pulled the starter and replaced the gasket and a new o ring on the stator housing along with a new stator harness to the e box. All tests good before dropping engine back in.

While the engine was out I adjusted the oil pump and checked all bolts for tightness and replaced all hose clamps. I also degreased the entire inside of the engine compartment. It was pretty nasty. The boat appears to have sat outside for the last season.

Here's some pics of that project:

I don't have pictures of the new stator but it's on there and timed correctly. I have dropped the engine back in and moved to the starboard engine. This engine had good compression. 153 and 154 iirc. The stator tested good and the carbs were rebuilt on this engine also. I have paperwork on the sbt engine and the carbs. It also appears that the top end had been rebuilt. New, unpainted gaskets lead me to think that. Also the compression is very good. I replaced the hose clamps and checked oil pump operation and adjustments. Pulled the cooling hoses and found no blockages or corrosion. I did find that the exhaust manifold gasket was missing and the 4 bolts on top were loose. This engine hasn't been run without the gasket that I can tell. All the issues I have come across look to be someone ran out of money to diagnose the boats problems. It has all new fuel lines, oil lines, all filters new.

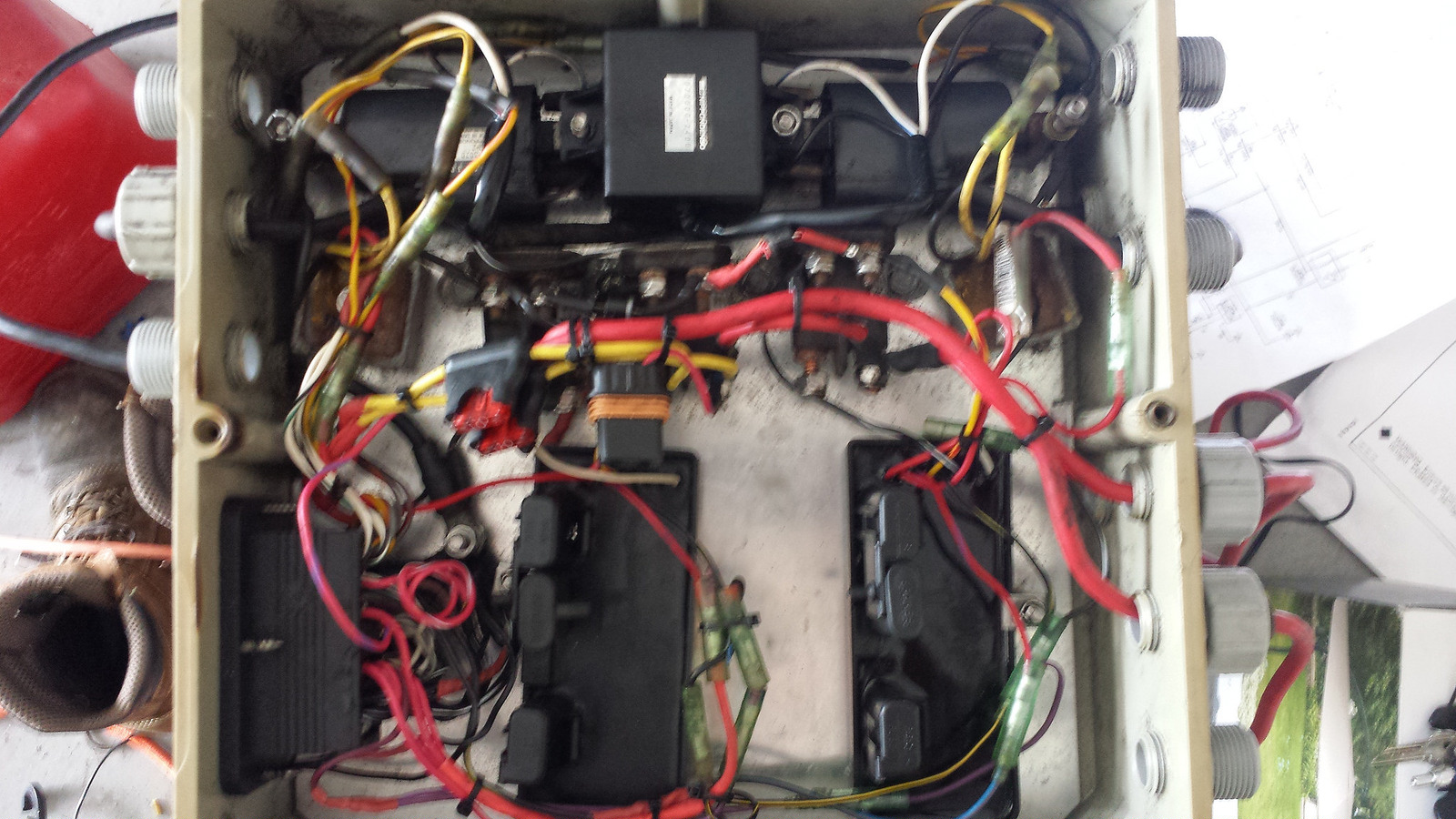

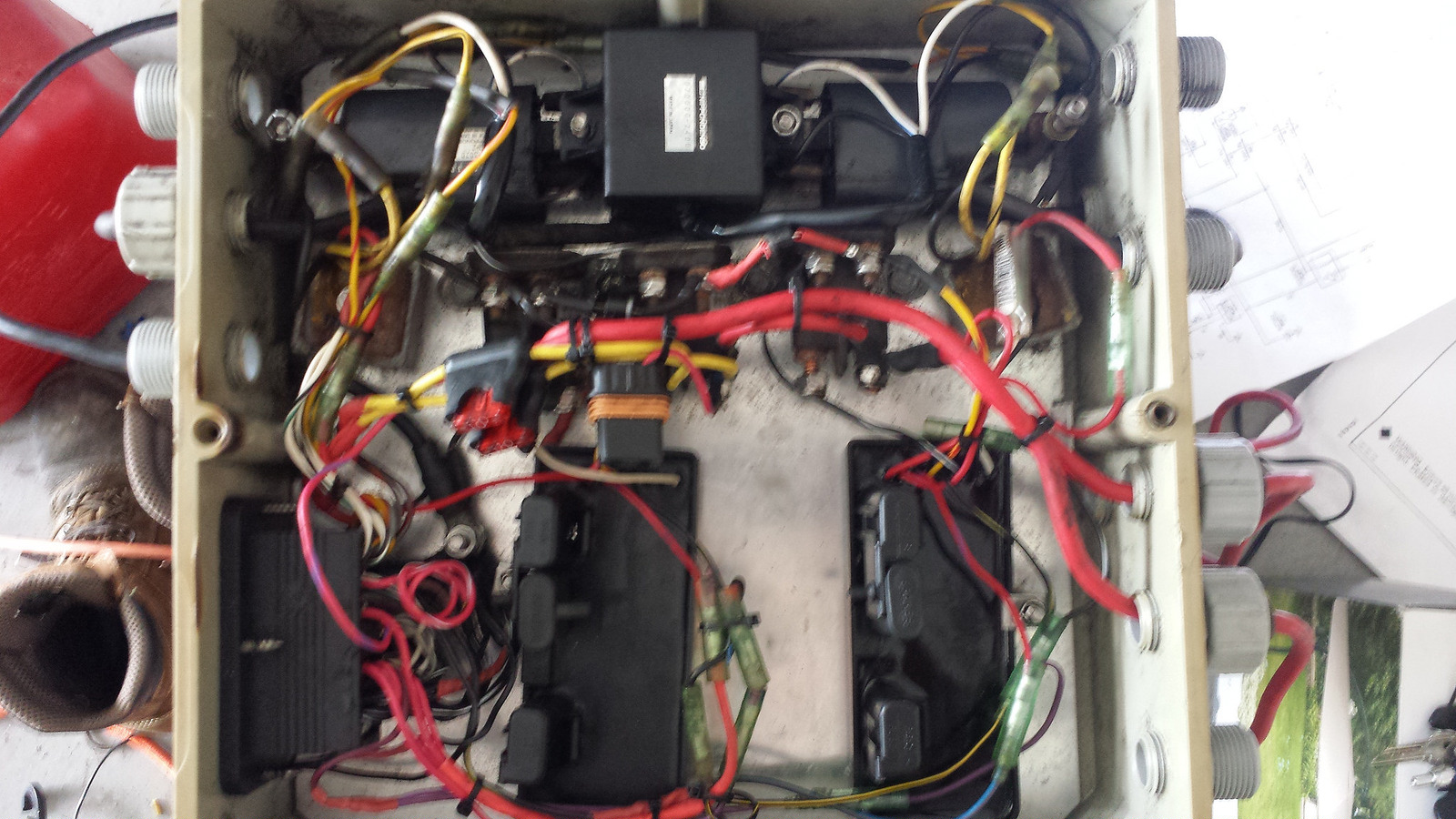

Now to the mpem. This took some research. To start off, the e box was in process of a mpem bypass from what I could see.

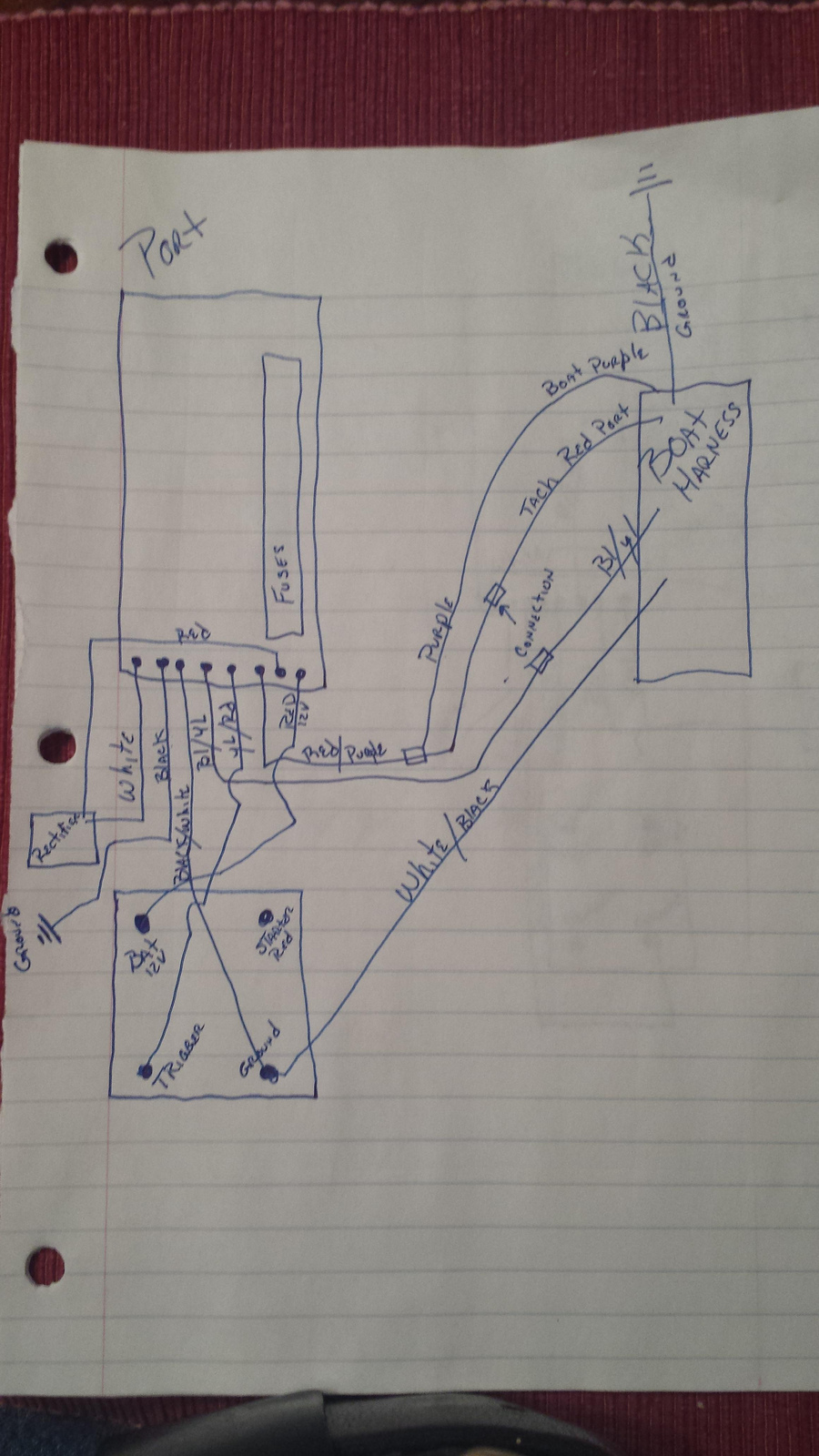

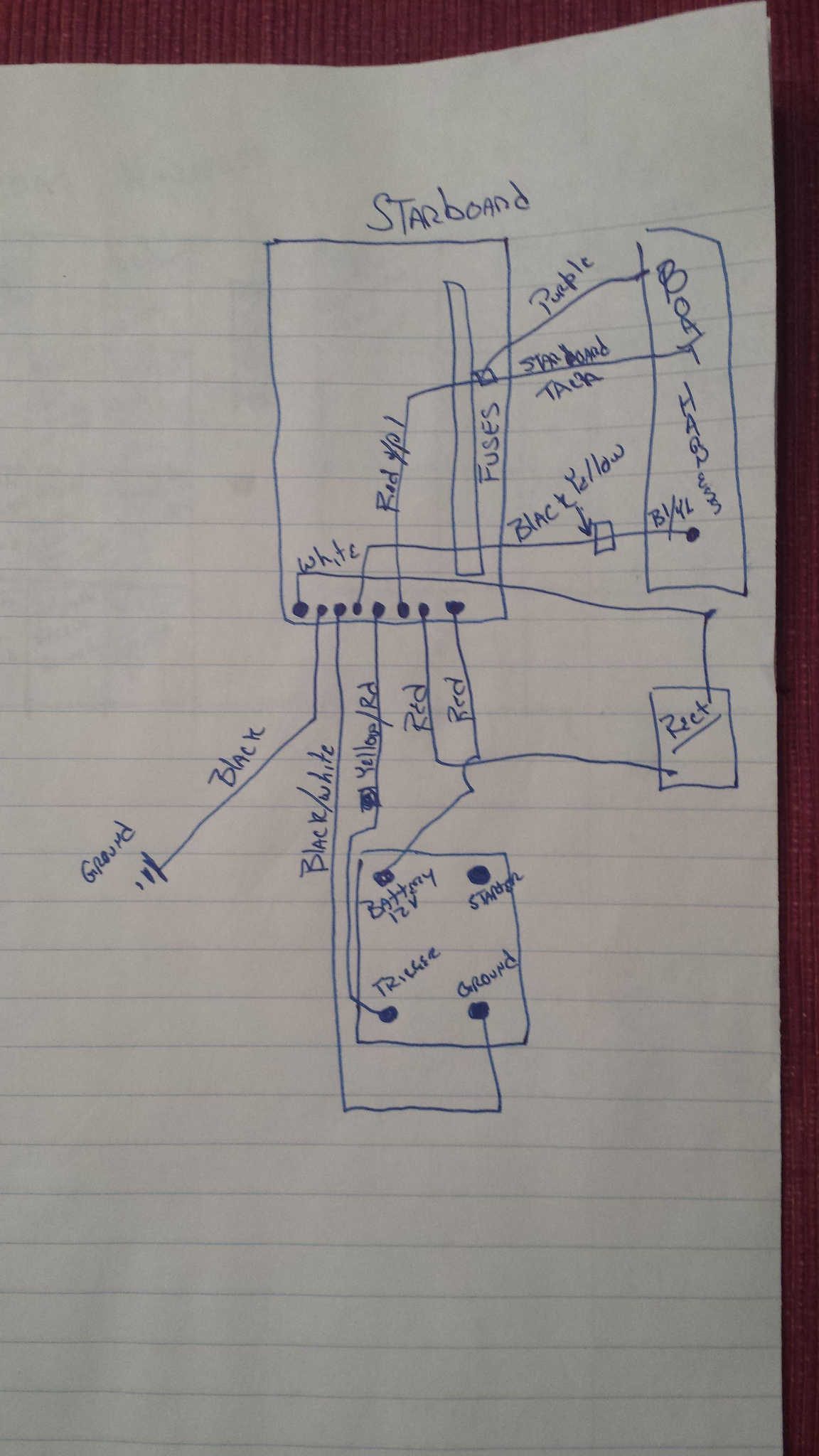

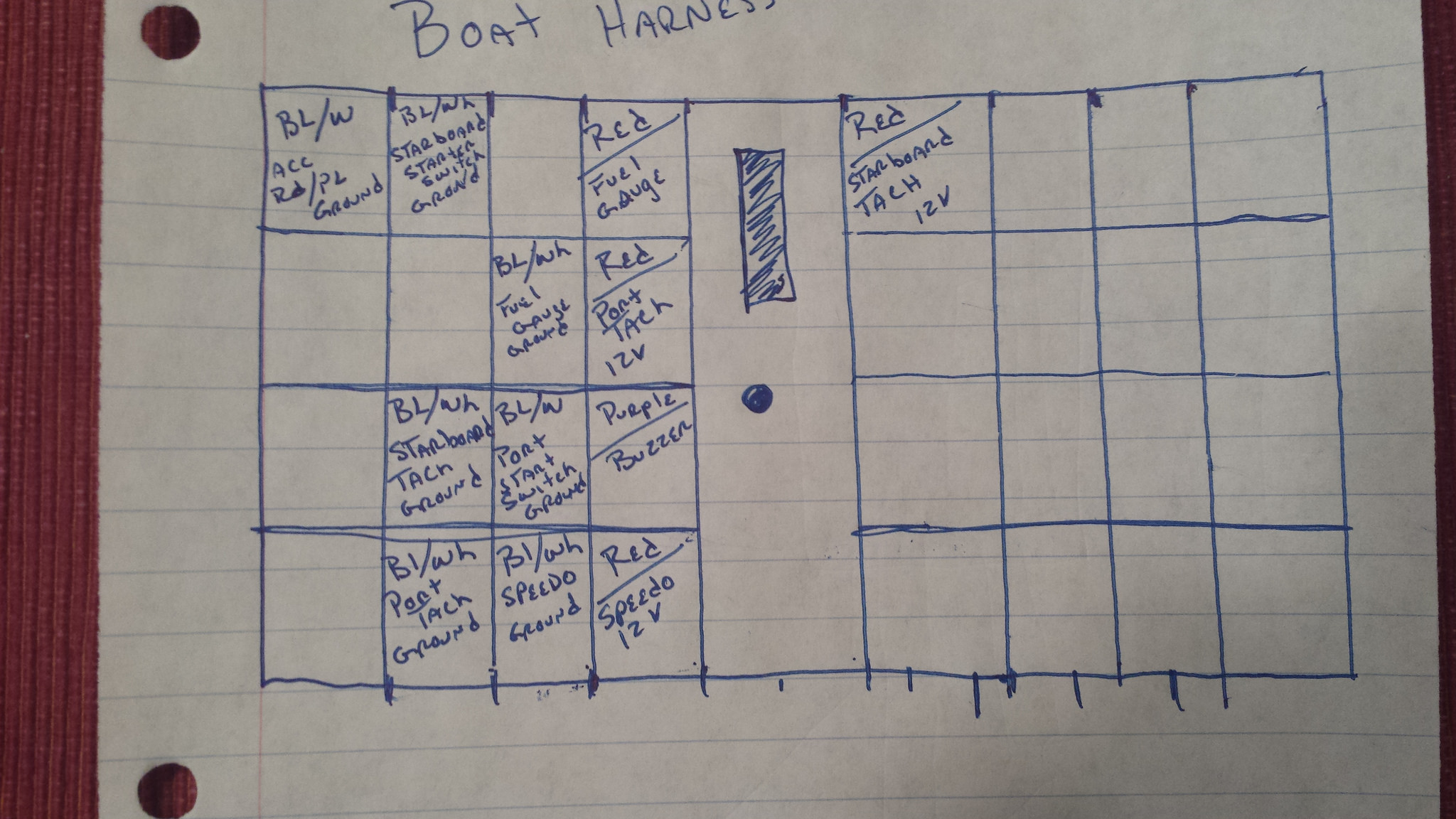

I took all the wiring nuts off and the aftermarket rev limiters off and tested the mpem on the bench. The notorious diode had blown, and I stopped there. With the blown stator and all the attempted bypassing, I decided not to chance it when I need reliability. I searched and searched for a how to do the dual mpem setup. I found freelancers and some companies doing it for 95 and up but nothing for 94 speedster. I bought 2 mpems from 93 94 skis. Part numbers were 278000305 and 278000071. I also got the wiring diagram from a 94 speedster, a 93 ski (with the 5 wire stator and 657x) and a 94.5 speedster (no dess). My boat has the dess post with the 3 wires (black, black/yellow, and white/gray)

I wired each engine with its own mpem to the 93 ski setup. I used the dess wiring for the ground kill switch. I put the e box temporarily in the boat and hooked up the engines to the box. Switched the fuel on, primed the engines, and put the dess on and hit the port starter, and it fired up first turn. No choke. Idled smooth for about a minute, and I was very happy with the results. Pulled the dess key off the post, engine shut off immediately and cleanly. Just as I had hoped. Same for the starboard engine. I am working on the accessories and gauges atm, and waiting on a gasket also. This is where I stand to date

While the engine was out I adjusted the oil pump and checked all bolts for tightness and replaced all hose clamps. I also degreased the entire inside of the engine compartment. It was pretty nasty. The boat appears to have sat outside for the last season.

Here's some pics of that project:

I don't have pictures of the new stator but it's on there and timed correctly. I have dropped the engine back in and moved to the starboard engine. This engine had good compression. 153 and 154 iirc. The stator tested good and the carbs were rebuilt on this engine also. I have paperwork on the sbt engine and the carbs. It also appears that the top end had been rebuilt. New, unpainted gaskets lead me to think that. Also the compression is very good. I replaced the hose clamps and checked oil pump operation and adjustments. Pulled the cooling hoses and found no blockages or corrosion. I did find that the exhaust manifold gasket was missing and the 4 bolts on top were loose. This engine hasn't been run without the gasket that I can tell. All the issues I have come across look to be someone ran out of money to diagnose the boats problems. It has all new fuel lines, oil lines, all filters new.

Now to the mpem. This took some research. To start off, the e box was in process of a mpem bypass from what I could see.

I took all the wiring nuts off and the aftermarket rev limiters off and tested the mpem on the bench. The notorious diode had blown, and I stopped there. With the blown stator and all the attempted bypassing, I decided not to chance it when I need reliability. I searched and searched for a how to do the dual mpem setup. I found freelancers and some companies doing it for 95 and up but nothing for 94 speedster. I bought 2 mpems from 93 94 skis. Part numbers were 278000305 and 278000071. I also got the wiring diagram from a 94 speedster, a 93 ski (with the 5 wire stator and 657x) and a 94.5 speedster (no dess). My boat has the dess post with the 3 wires (black, black/yellow, and white/gray)

I wired each engine with its own mpem to the 93 ski setup. I used the dess wiring for the ground kill switch. I put the e box temporarily in the boat and hooked up the engines to the box. Switched the fuel on, primed the engines, and put the dess on and hit the port starter, and it fired up first turn. No choke. Idled smooth for about a minute, and I was very happy with the results. Pulled the dess key off the post, engine shut off immediately and cleanly. Just as I had hoped. Same for the starboard engine. I am working on the accessories and gauges atm, and waiting on a gasket also. This is where I stand to date

Last edited by a moderator: